Optimized Assembly Lines for Enhanced Manufacturing Efficiency

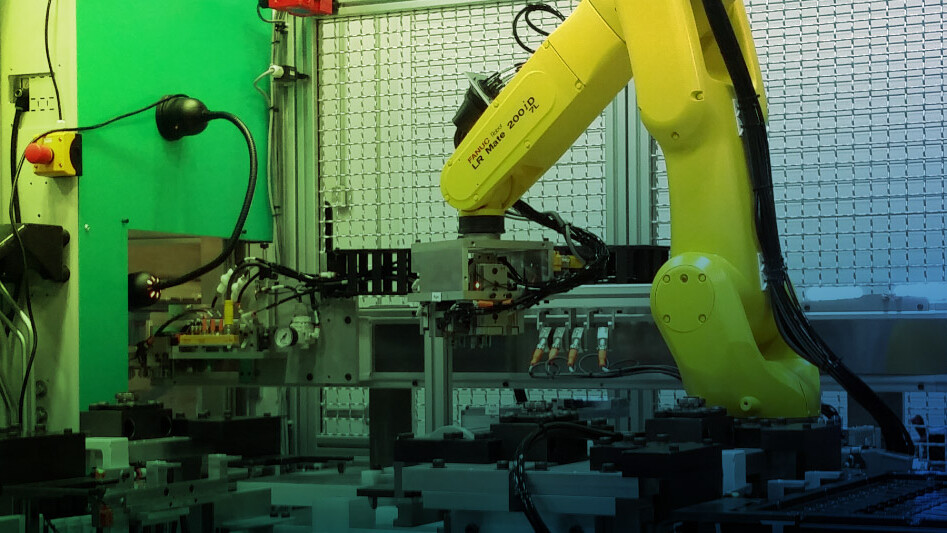

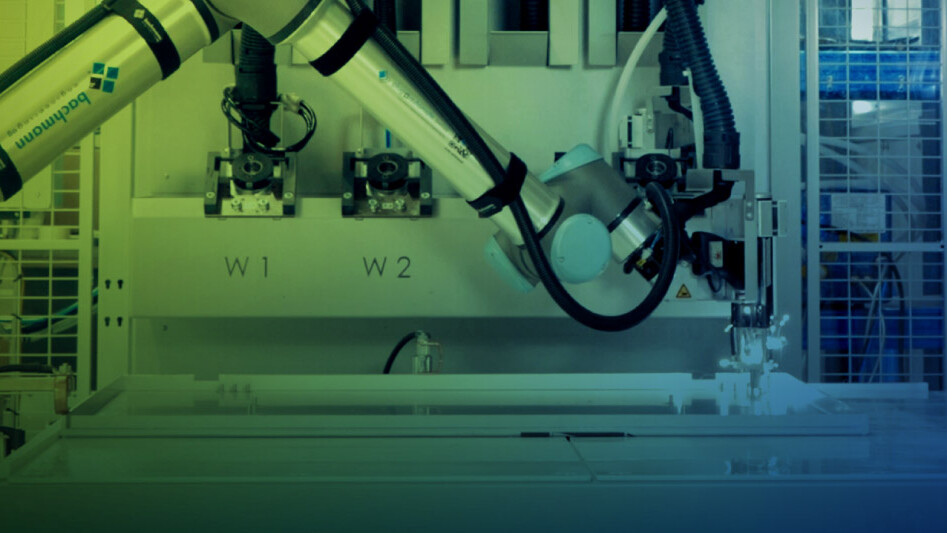

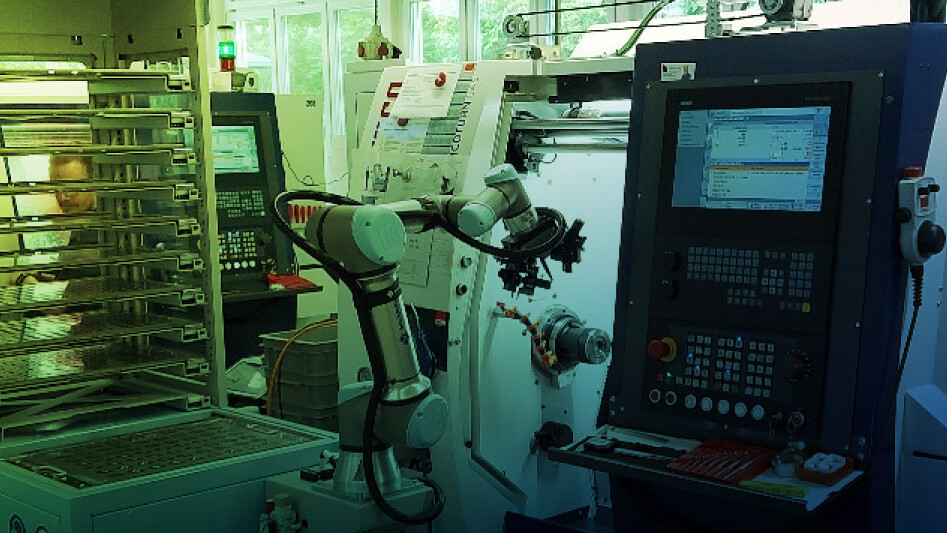

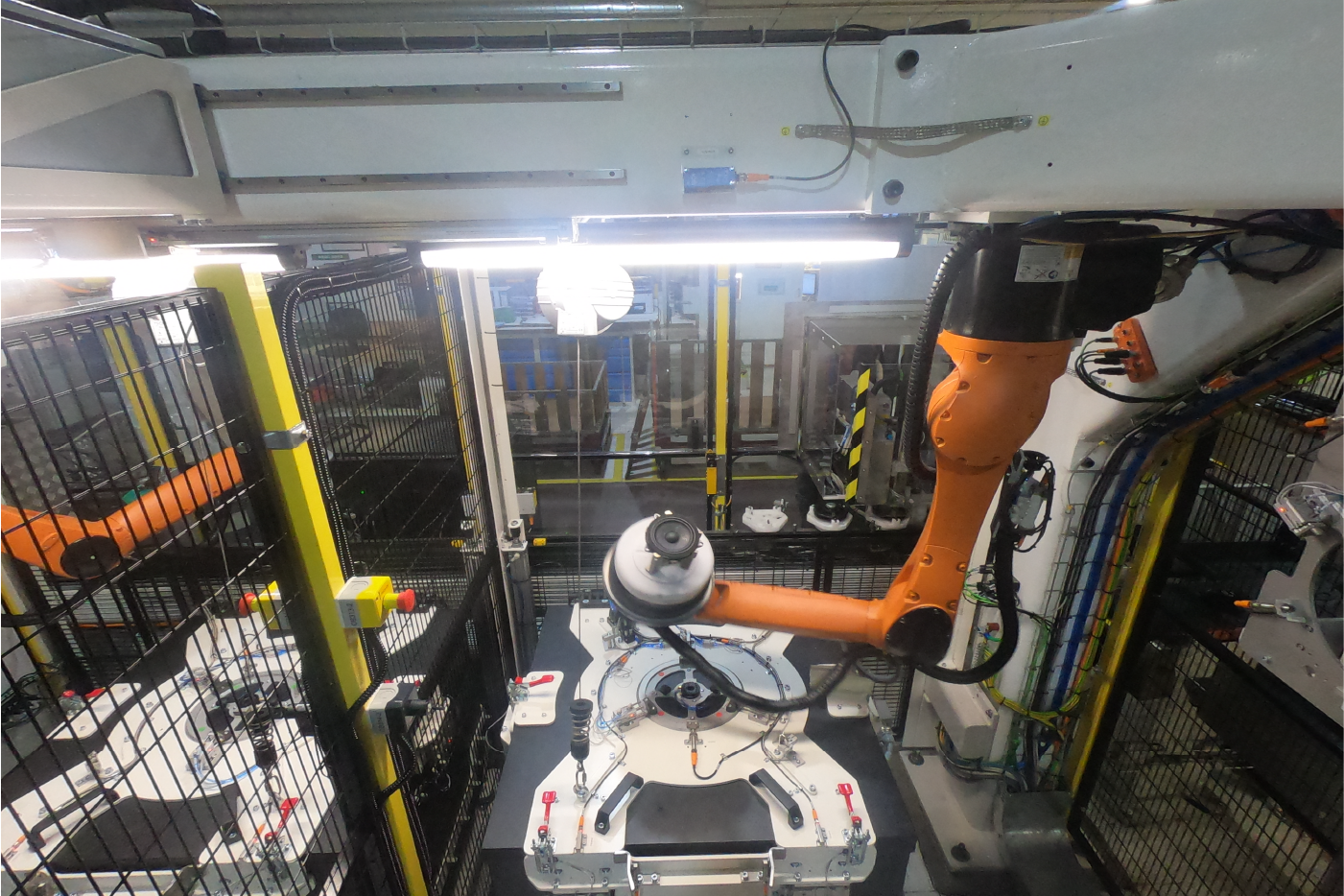

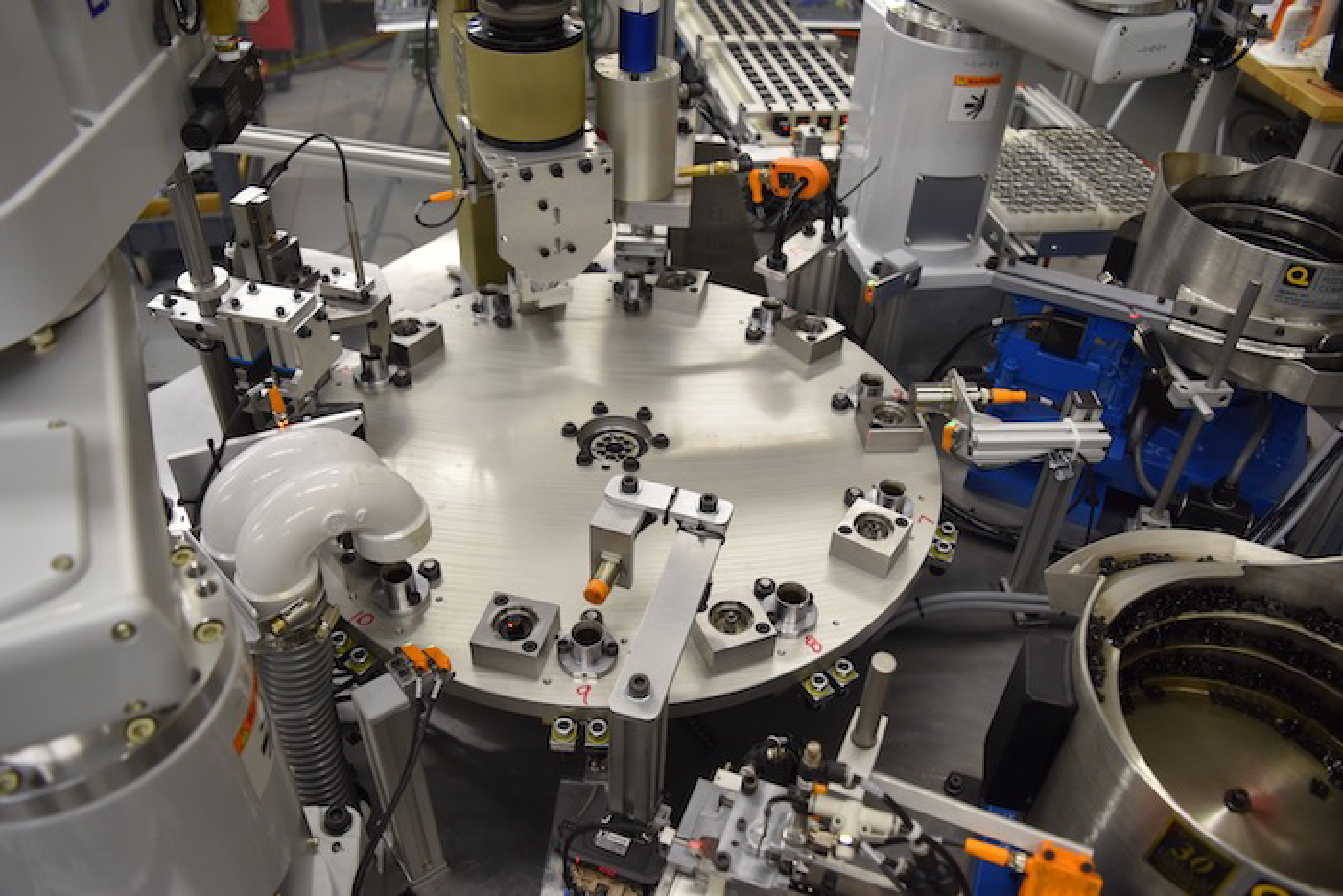

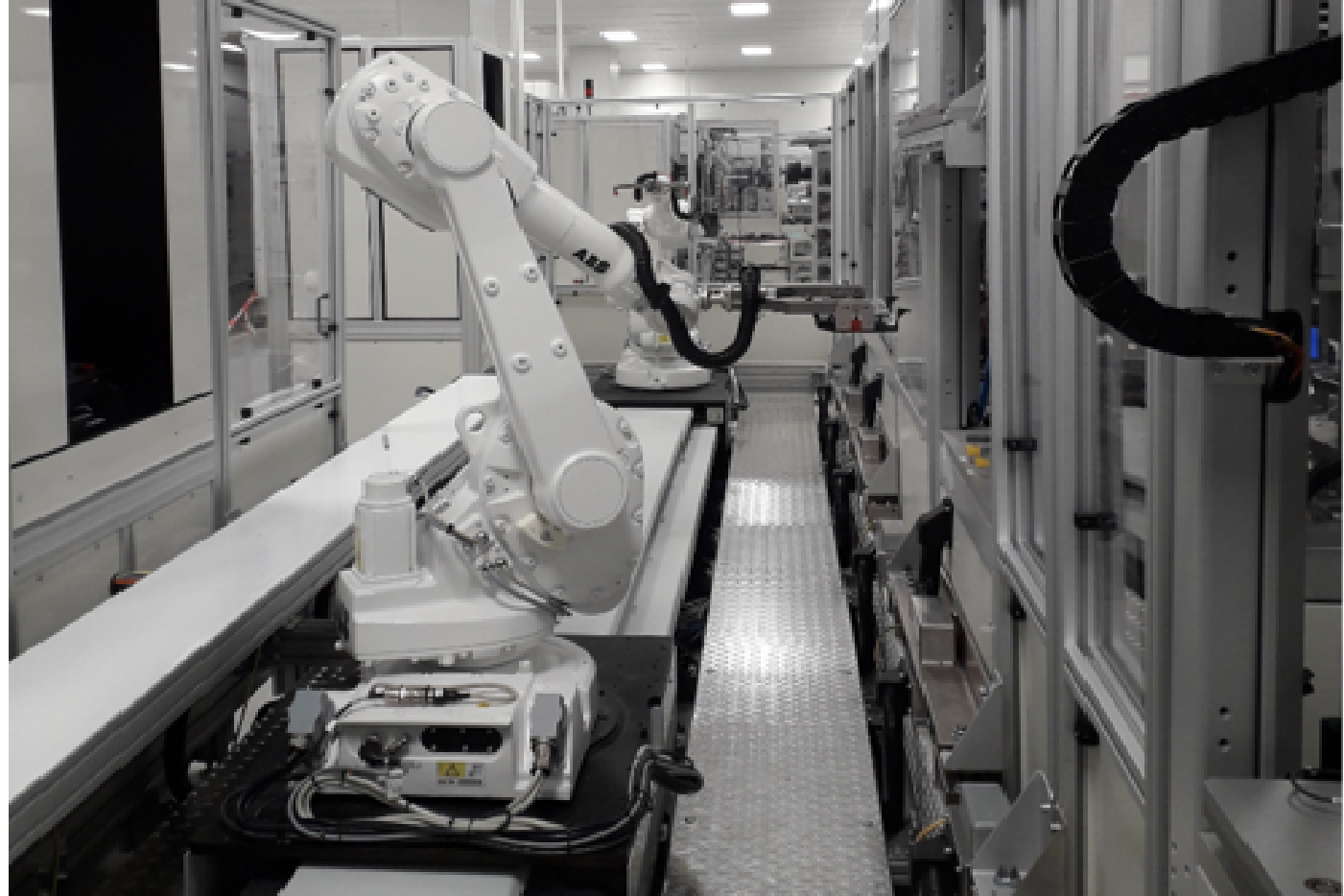

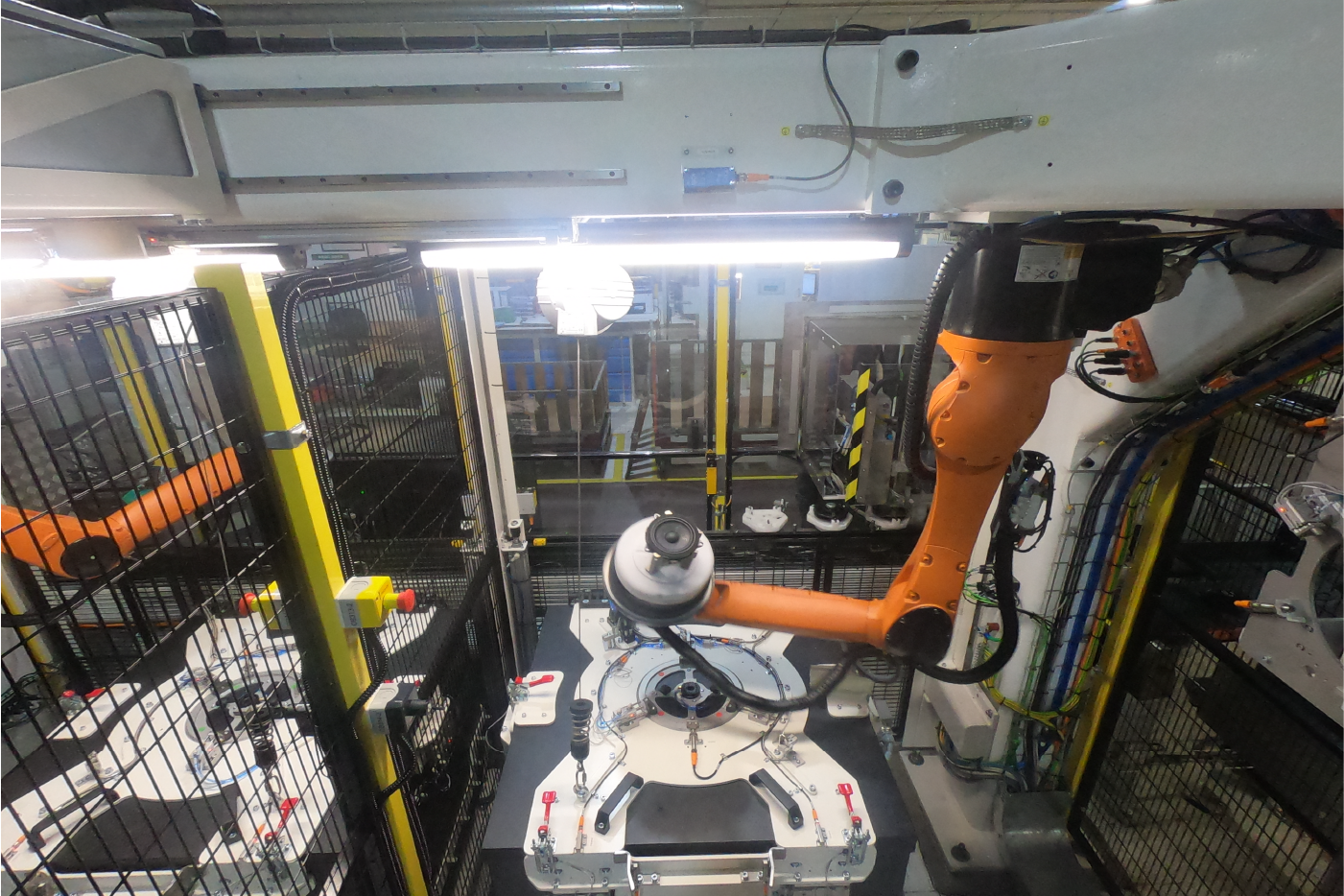

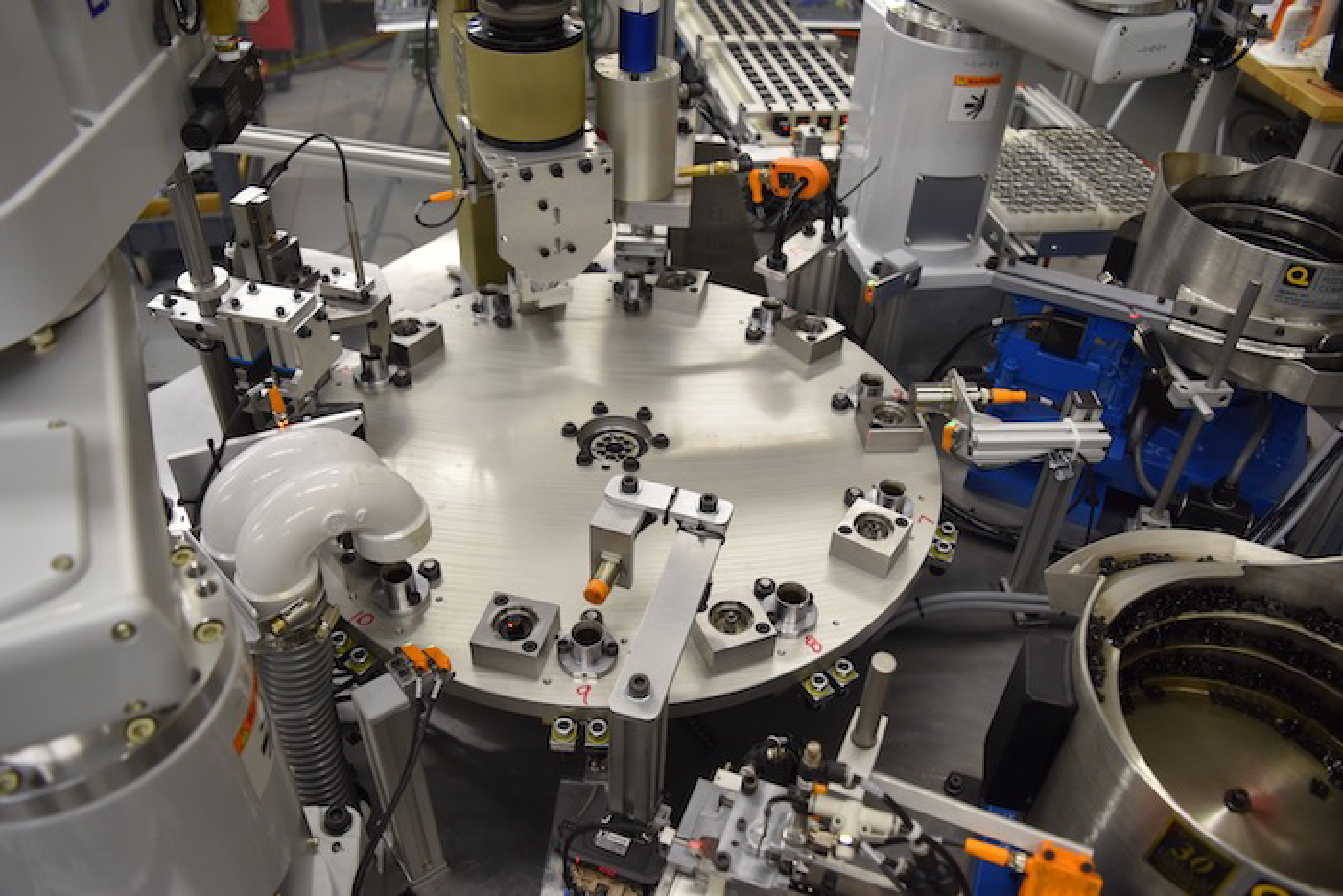

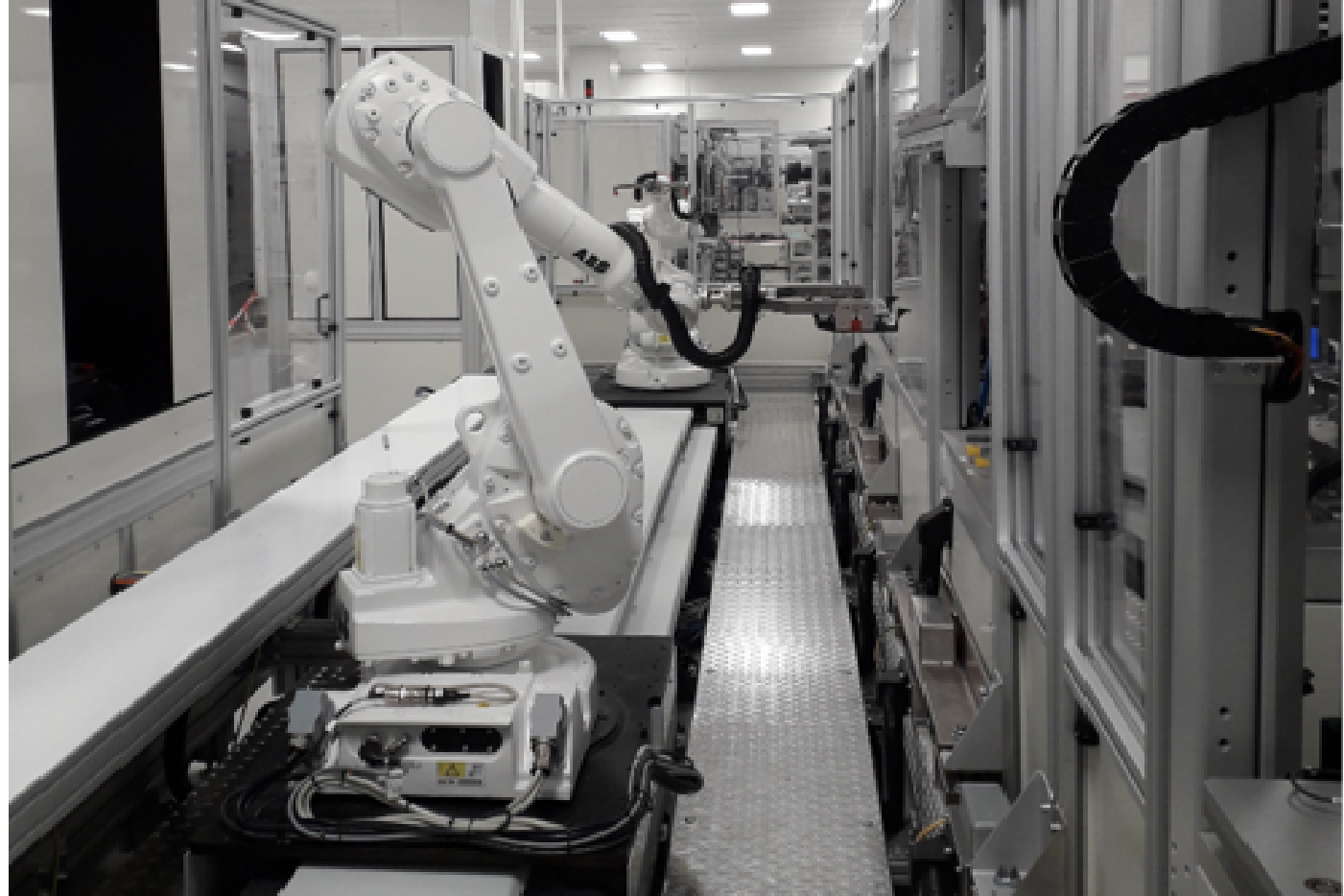

In the competitive realm of manufacturing, ensuring the quality and efficiency of assembly processes is crucial. Our assembly lines are meticulously developed based on a modular structure, designed for optimal layout and scalability to accommodate the specific assembly operations required. This modular approach allows for an adaptable layout that can be configured in various forms, enhancing the flexibility to assemble different product models.

From the initial idea to commissioning and lifecycle support, we are committed to providing our customers with superior industrial solutions tailored to each unique need. Our lines are not only flexible in terms of layout but also in product handling, supporting the assembly of diverse models which is essential for adapting to changing market demands.

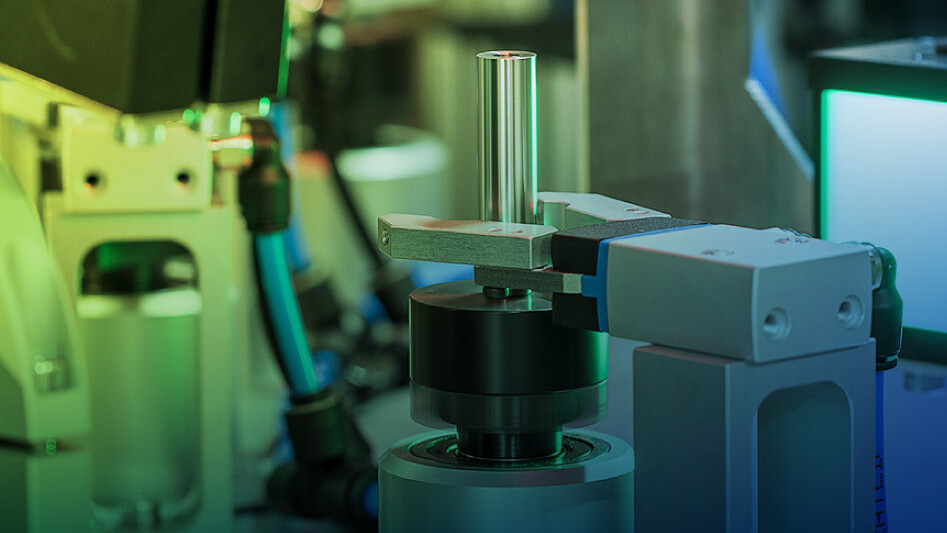

Moreover, our expertise extends to developing integrated solutions that enhance overall production efficiency. Each assembly line is equipped to integrate both fully automated and semi-automated processes, ensuring that our systems can evolve with your manufacturing needs. This integration capability allows for streamlined operations and a significant boost in production efficiency, ensuring that our customers maintain a competitive edge in their respective markets.

By focusing on smart design and flexible configurations, we empower manufacturers to achieve higher standards of quality and efficiency, paving the way for innovative solutions that meet the demands of modern production environments.

Our expertise:

- Heat stacking

- Pressing

- Fixing

- Bonding (LOCA/Structural)

- Gluing

- Screwing

- 2D&3D Inspection systems

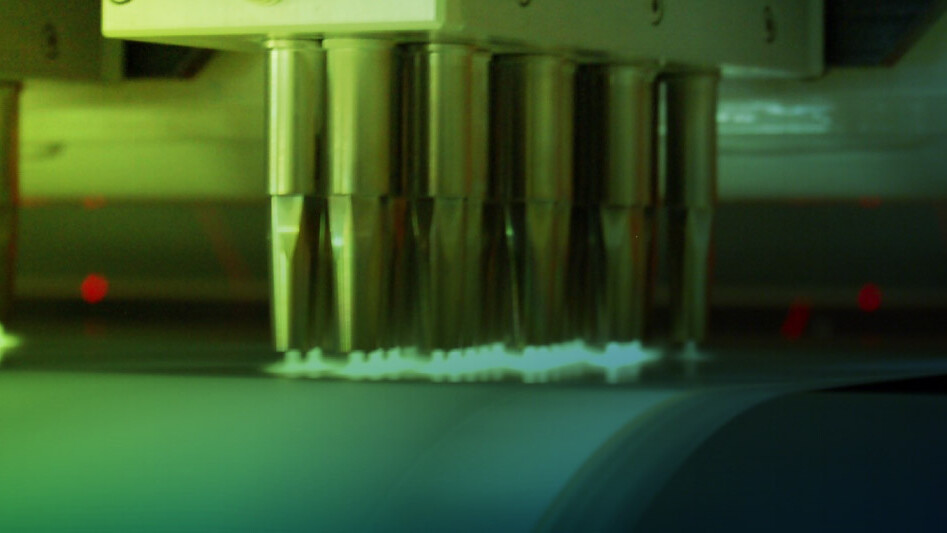

- Dispensing

- Dosing

- Welding

- Pick & Place

- Feeding systems

- Cleaning

Want to know more about this solution?

Share this content: