solutions

Automatic Sorting and Testing Cells

Precision Quality Control

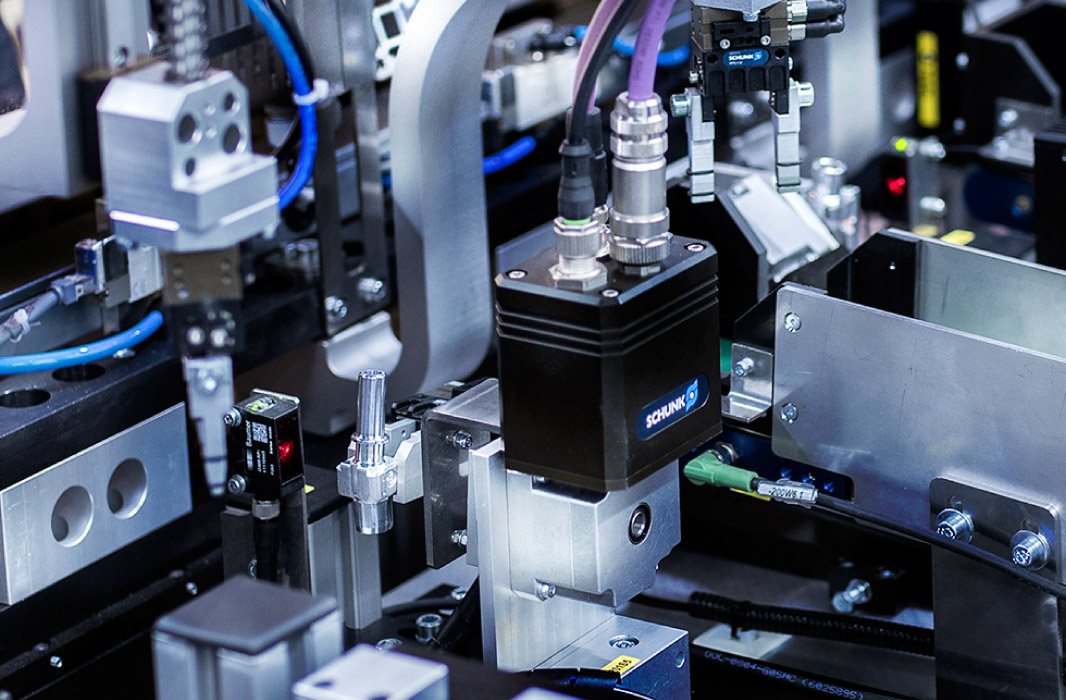

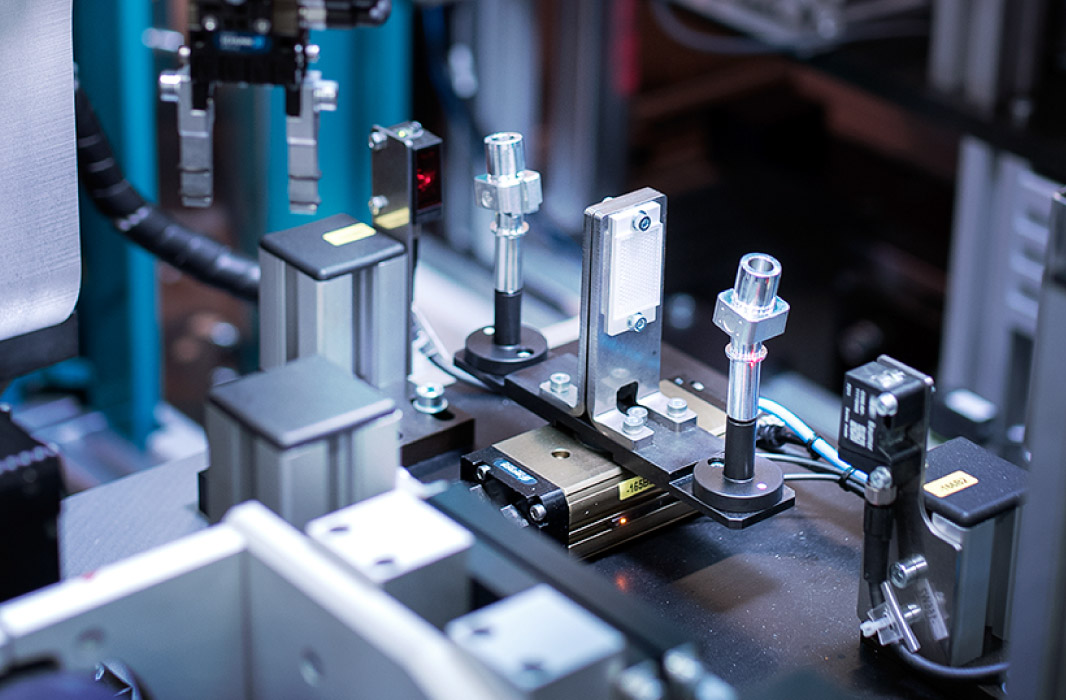

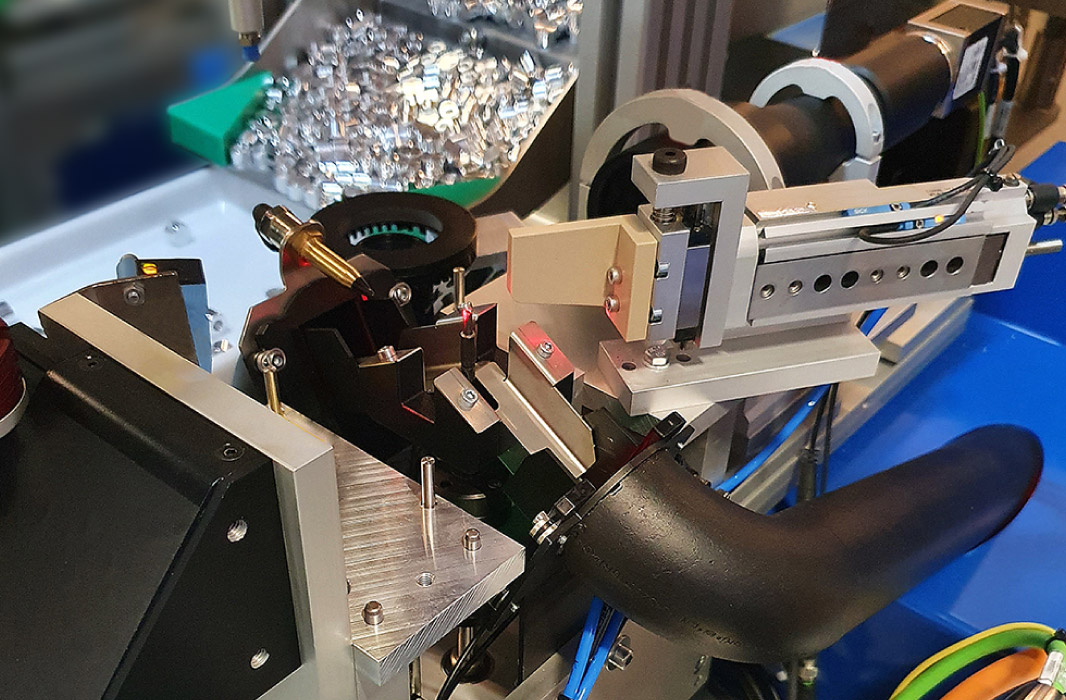

Leveraging our deep expertise in testing and measurement technology, we understand the critical impact of production inaccuracies and the high costs they can entail. Our suite of fully automatic testing machines is designed to ensure 100% quality control with minimal time investment. By combining advanced mechanical and electronic components in a modular design, we offer systems that are not only highly flexible and scalable but also space-efficient and user-friendly.

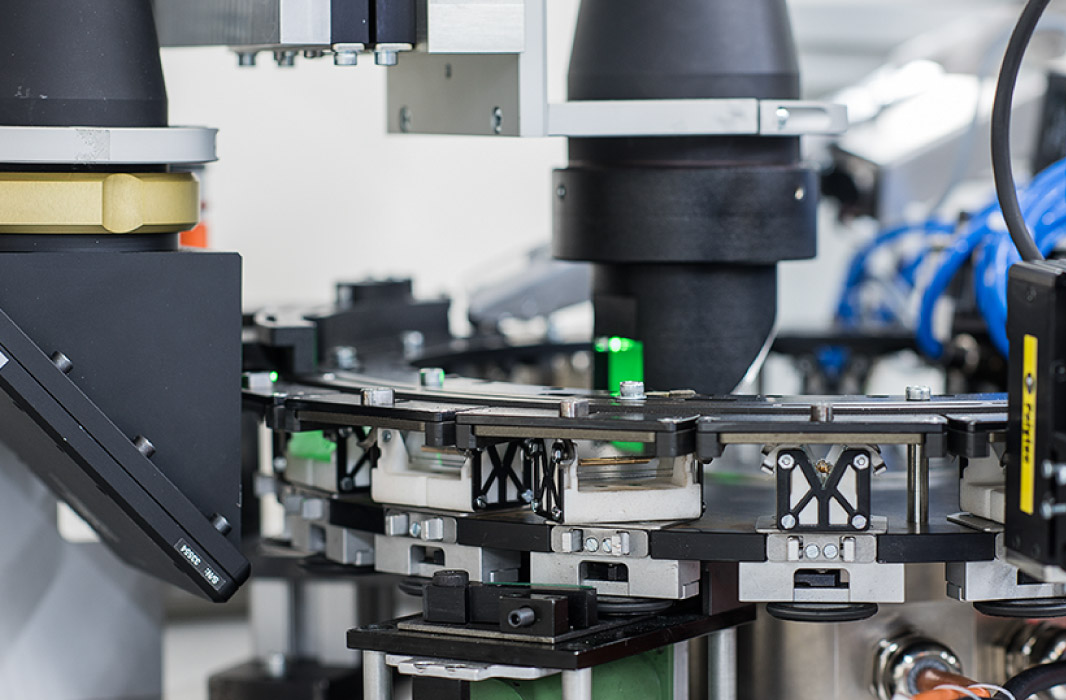

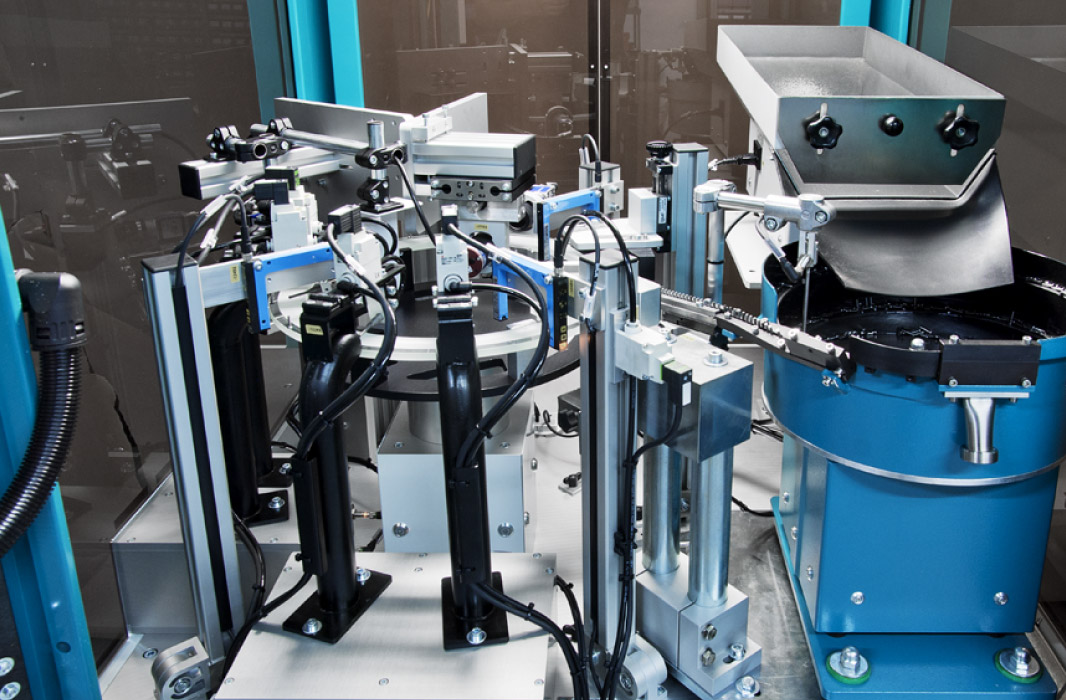

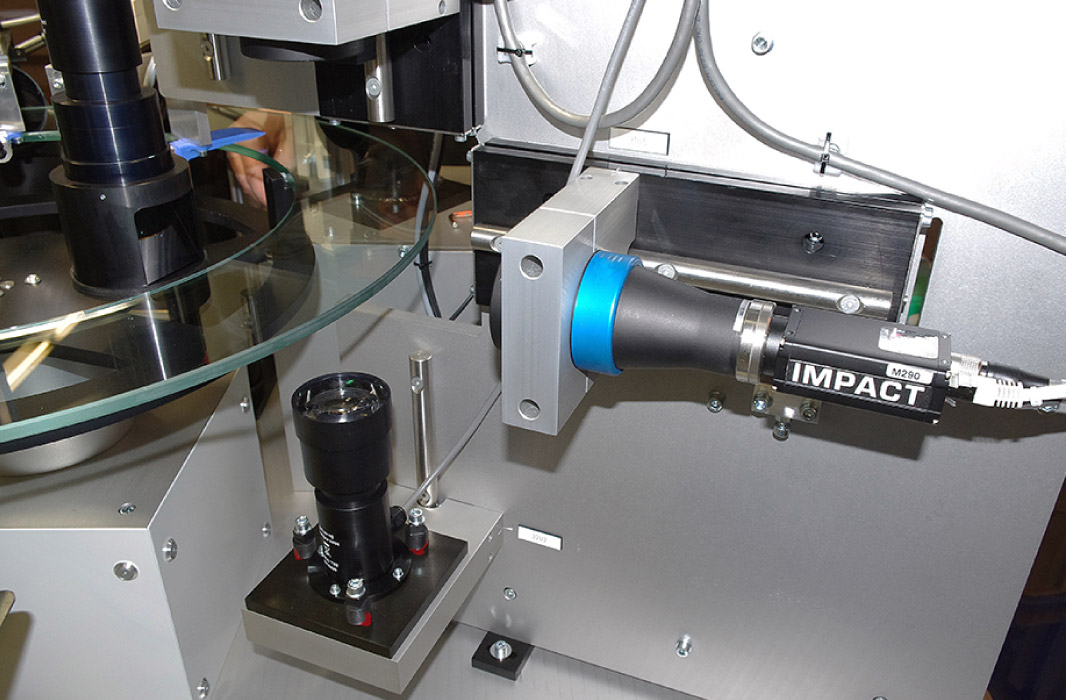

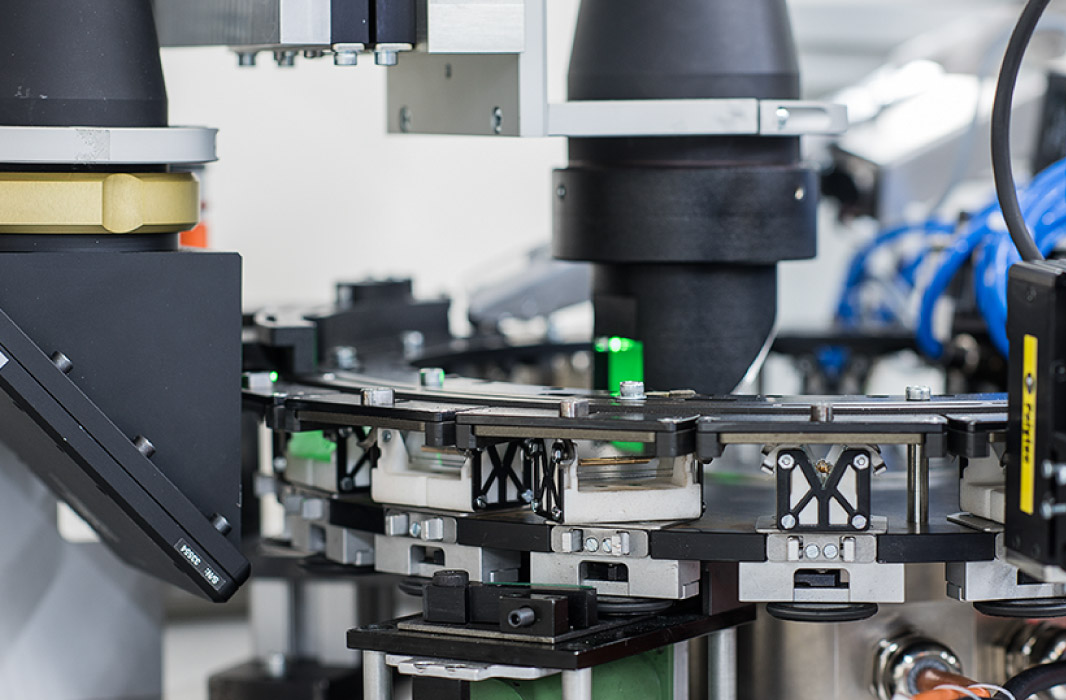

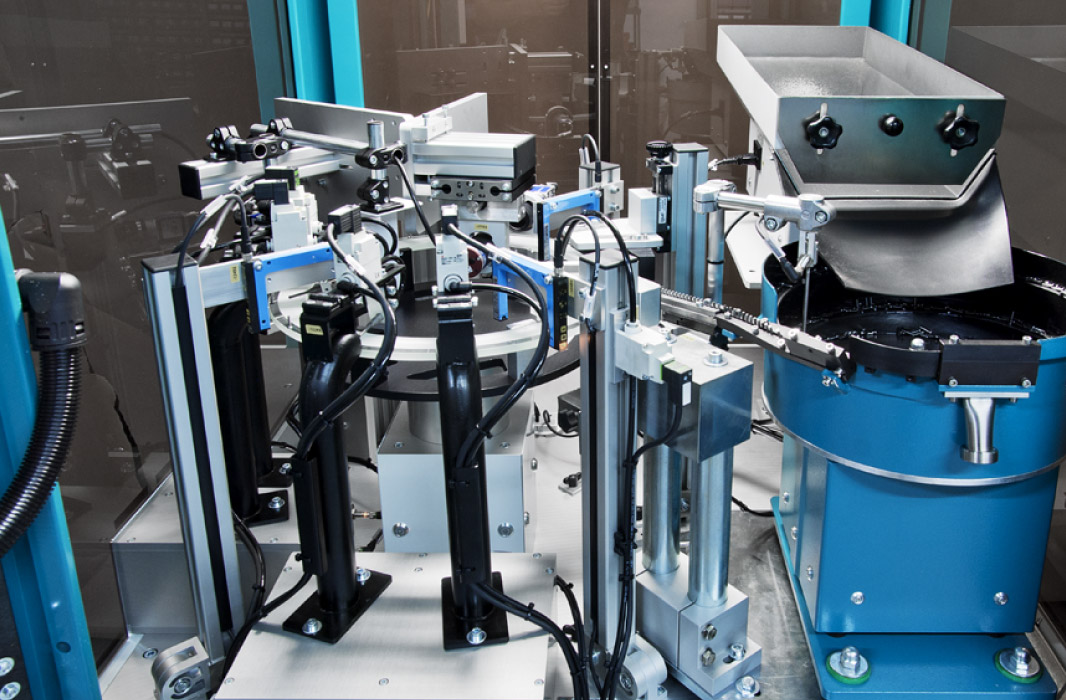

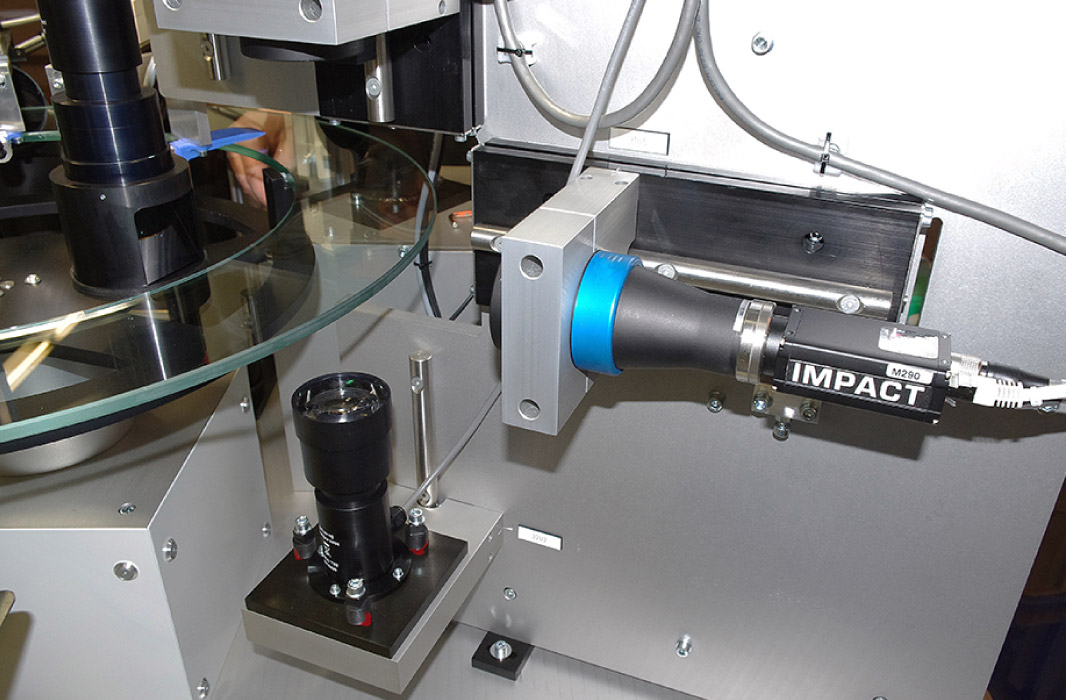

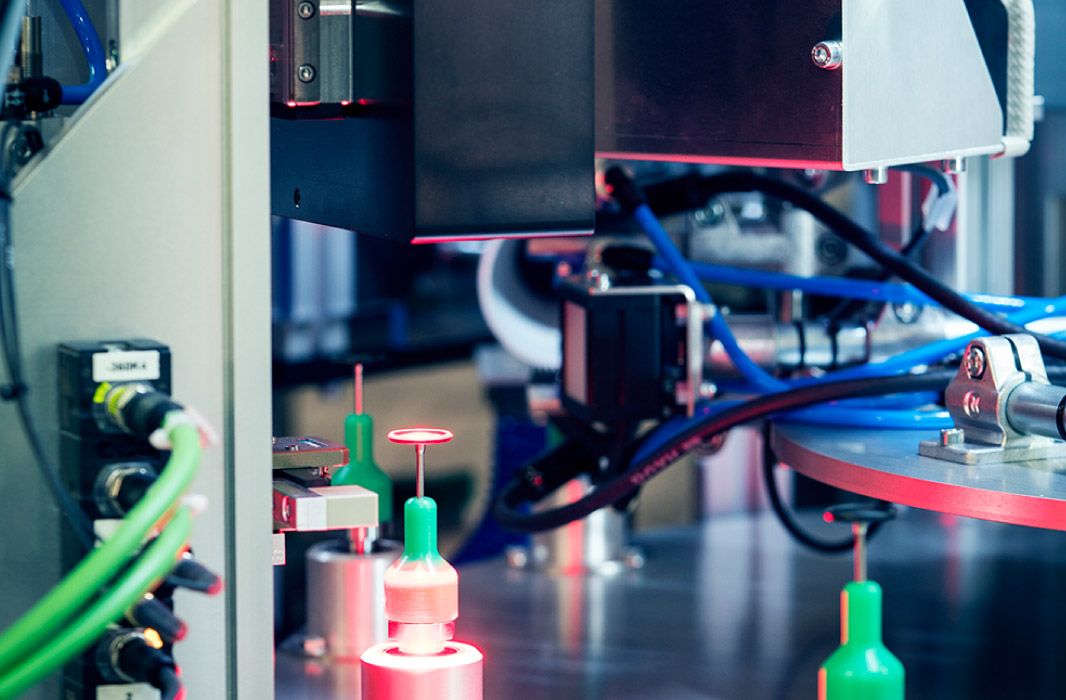

SONROND – the best of throughput

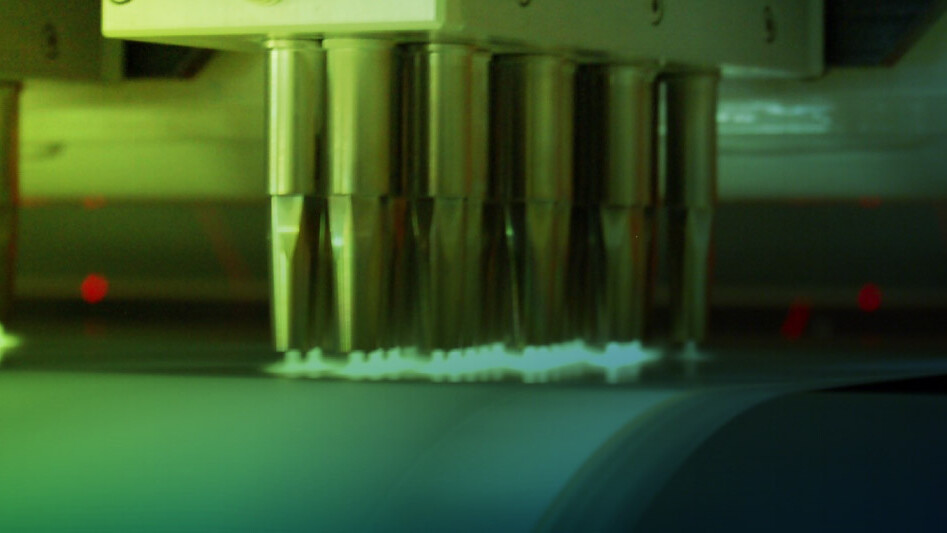

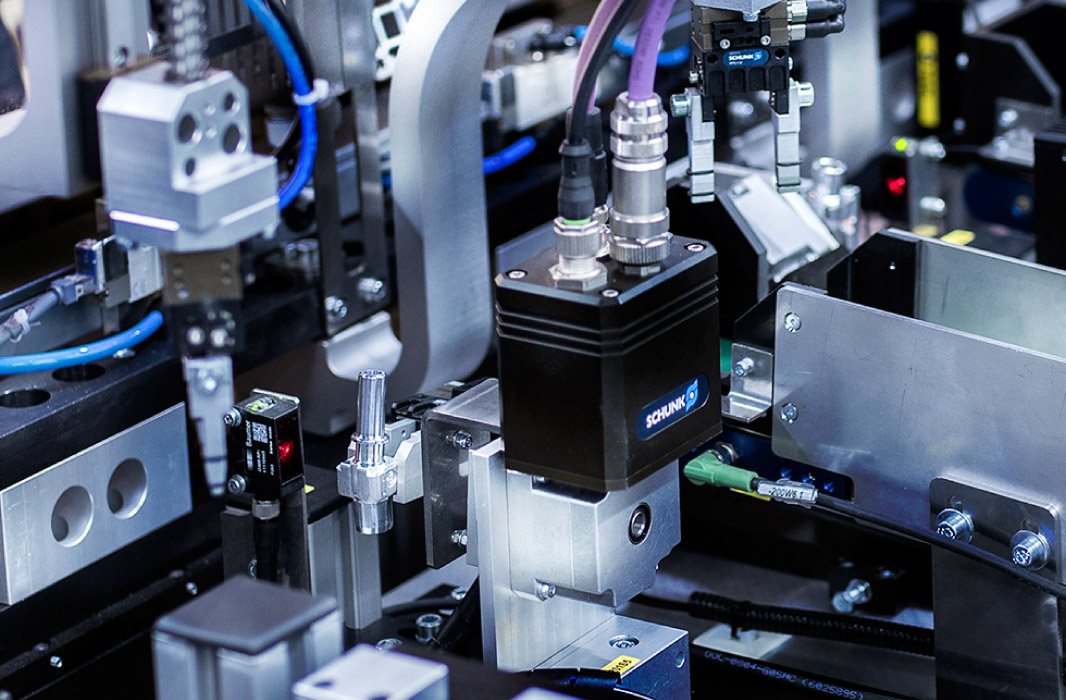

The SONROND Automatic Testing Machine distinguishes itself with high-performance test and measurement systems, an intuitive human-machine interface (HMI) for easy operation, and advanced PLC control featuring the latest in bus technology. It showcases a unique continuously rotating rotary table with a glass pane, allowing serial parts to be inspected from various angles by multiple cameras before being sorted. The highlight of the SONROND machine is its exceptional maximum output of 420 pieces per minute, making it a powerhouse for rapid parts inspection and sorting.

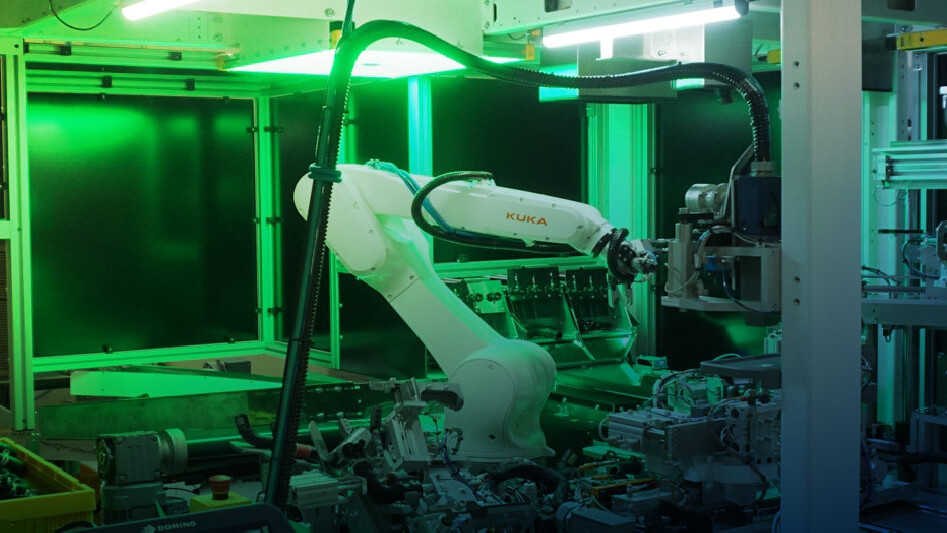

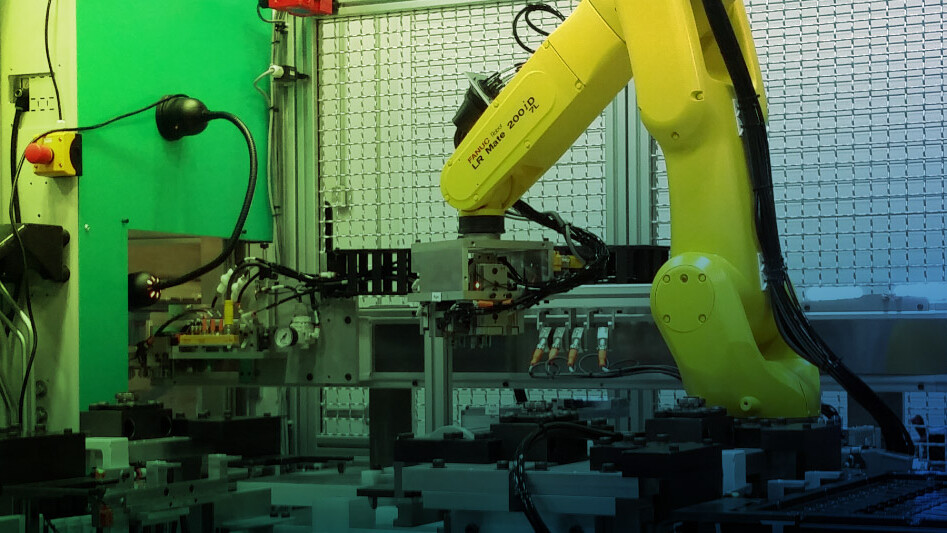

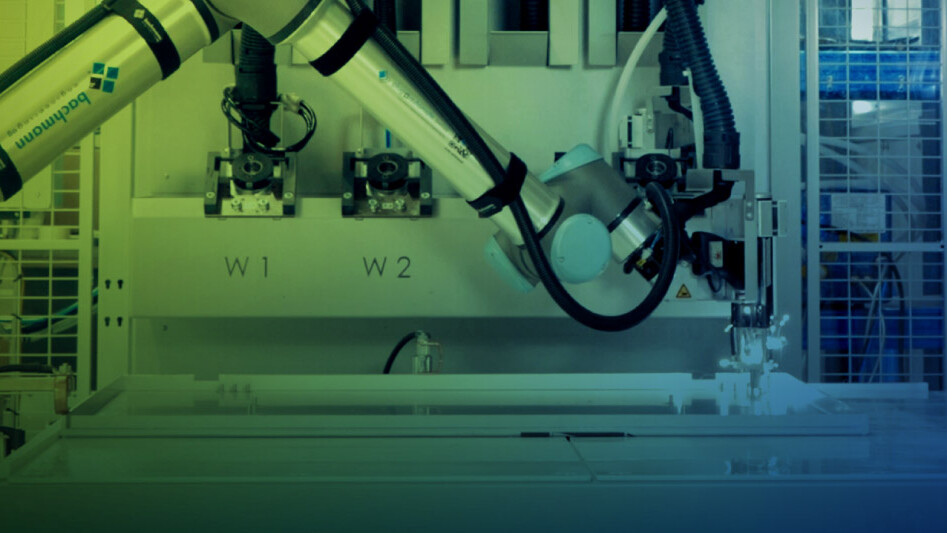

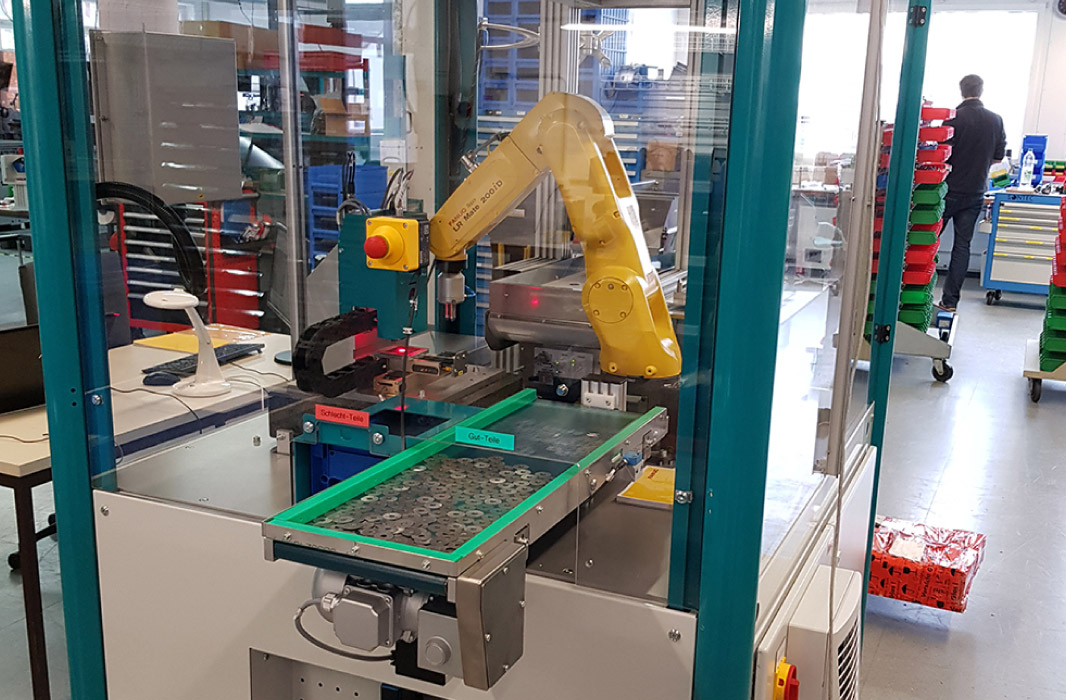

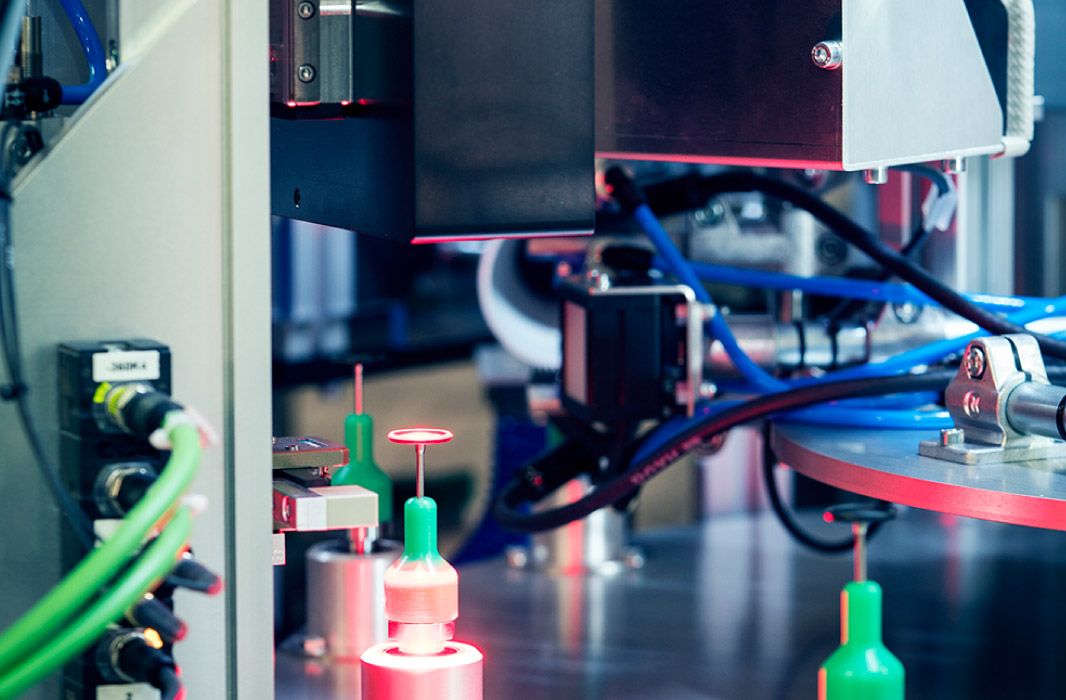

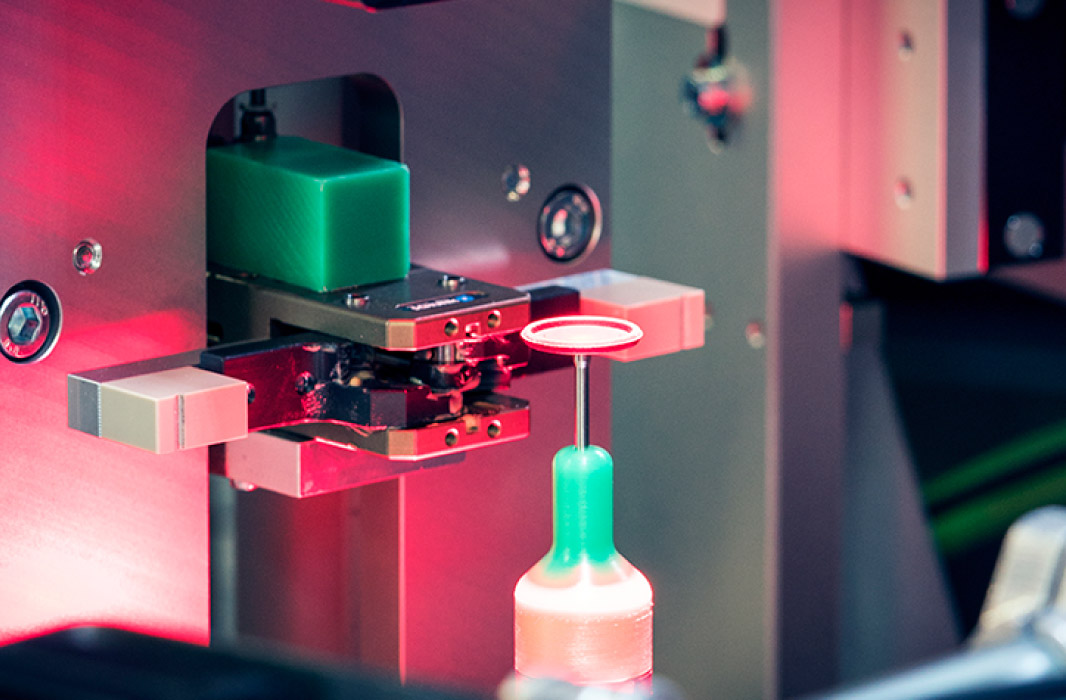

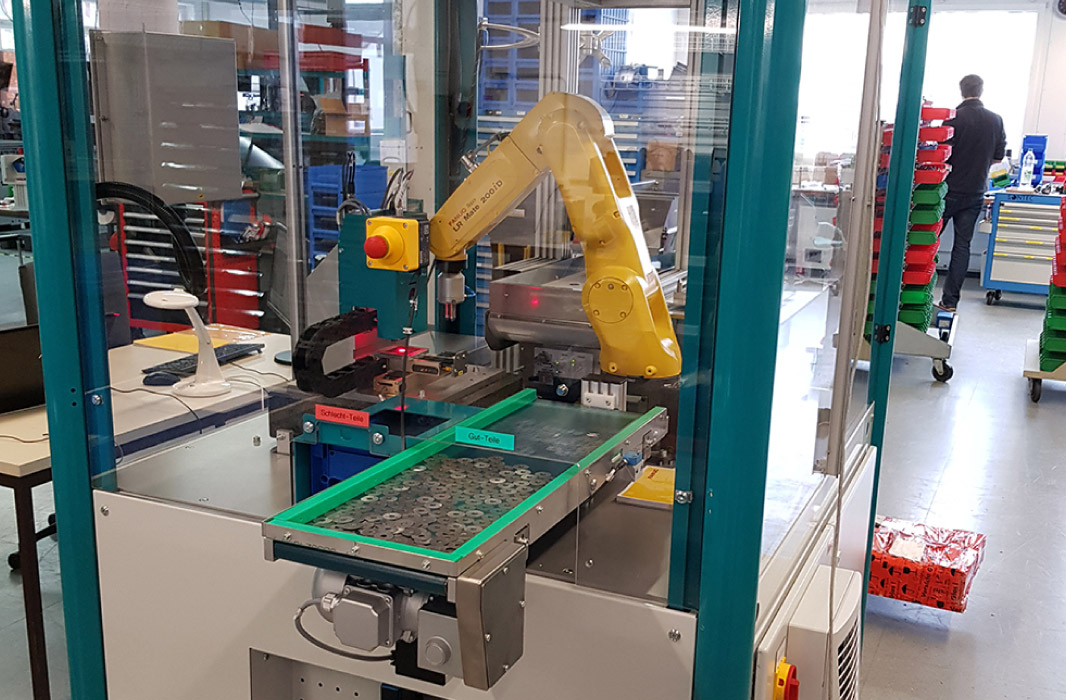

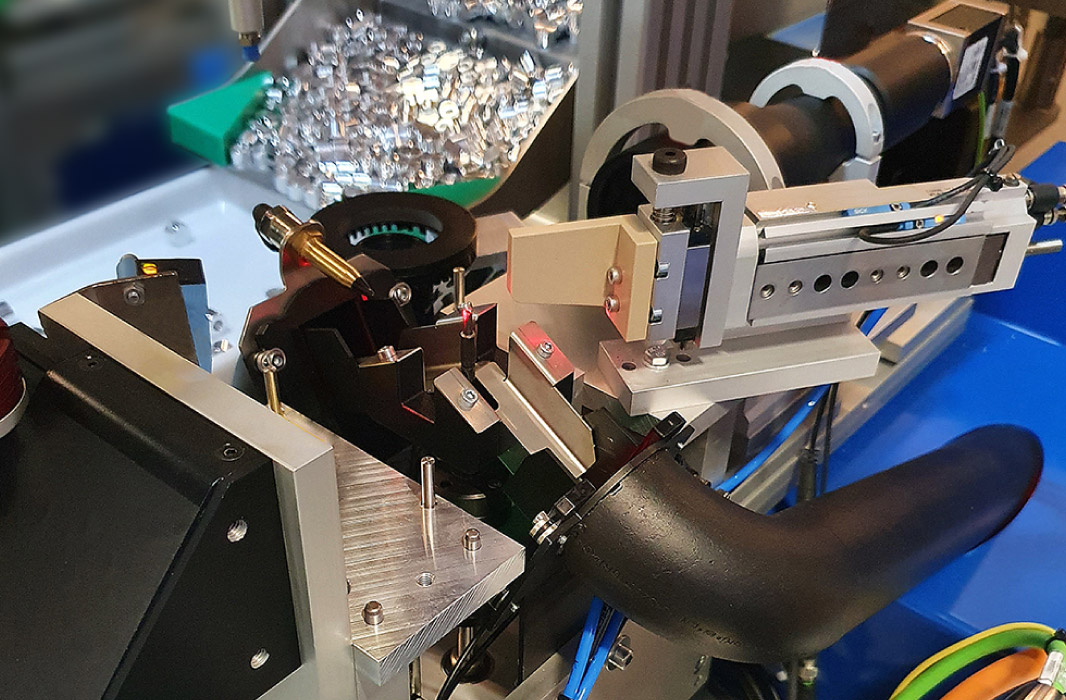

SONFLEX- the best of flexibility

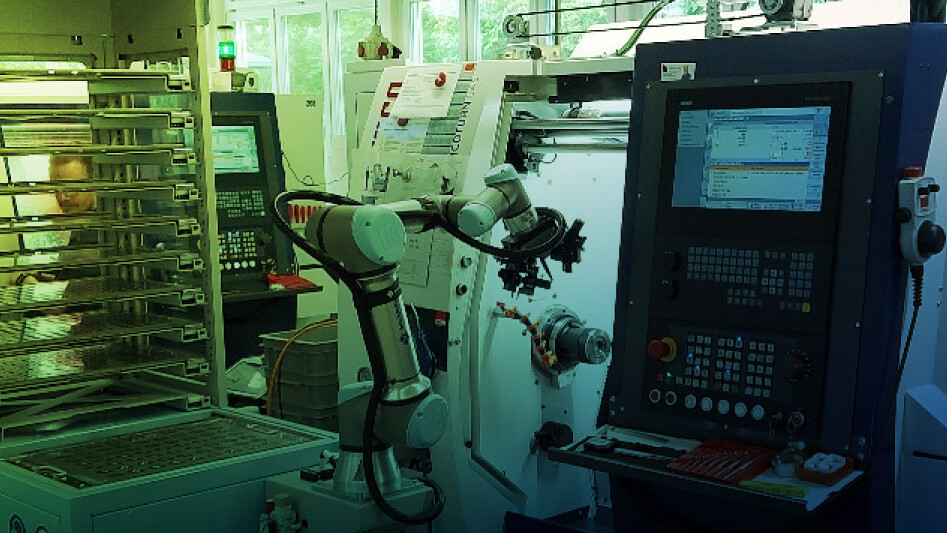

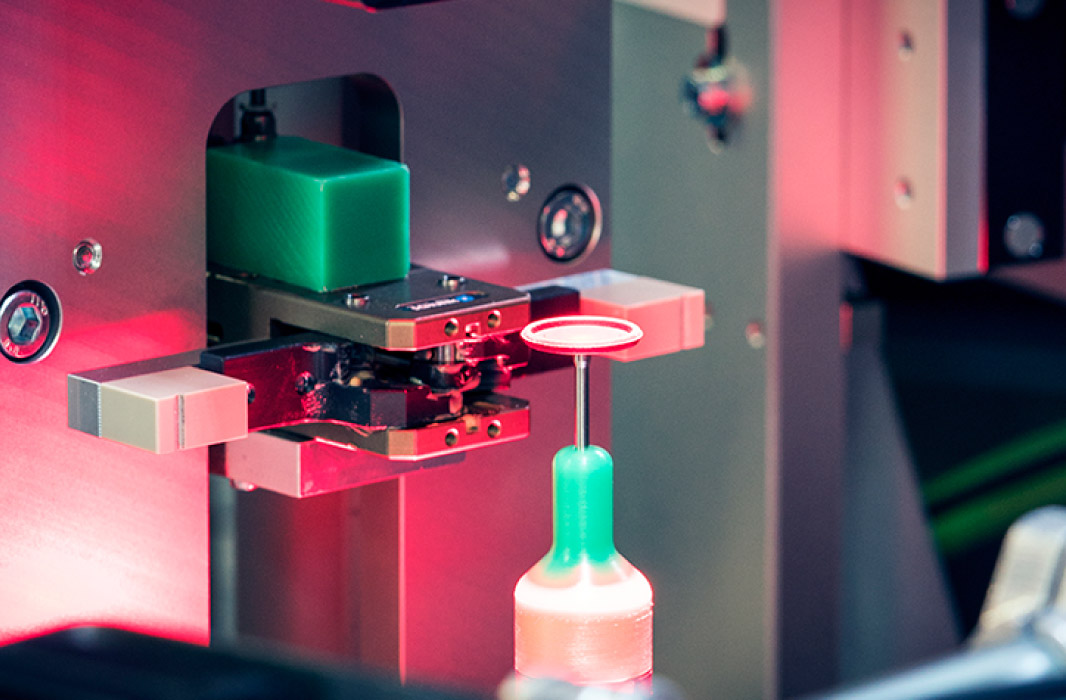

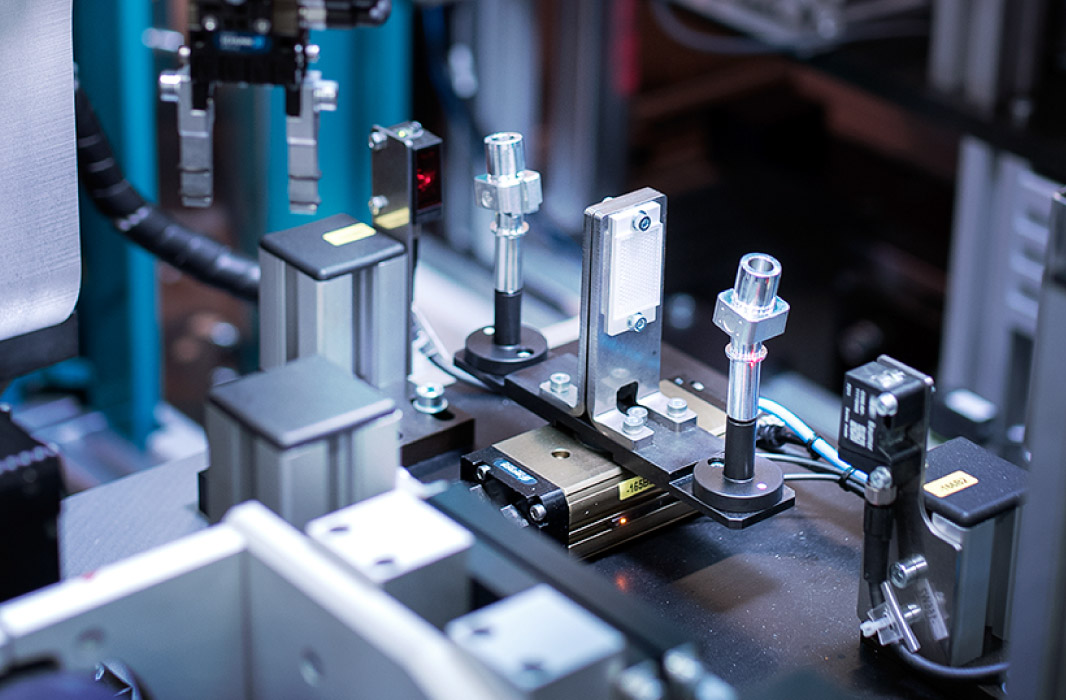

In contrast, the SONFLEX machine is designed around the concept of versatility and very high flexibility. It integrates optical inspection, tactile measurement, and laser measuring sensors with a wide range of inspection and assembly technologies. A robot meticulously places series parts into different testing and assembly stations, which are cleverly arranged to maximize the efficiency of the processing area. The SONFLEX stands out for its adaptability, capable of handling a diverse array of testing and assembly tasks with ease. Its design encourages very high flexibility and supports easy process extensions, catering to evolving manufacturing needs.

Our expertise:

- High-Performance Testing

- Rapid Parts Inspection

- Maximum Output

- Intuitive Operation

- Advanced PLC Control

- Continuous Rotary Inspection

- Versatile Assembly

- Very High Flexibility

- Process Adaptability