solutions

Industry 4.0

Navigating the Fourth Industrial Revolution

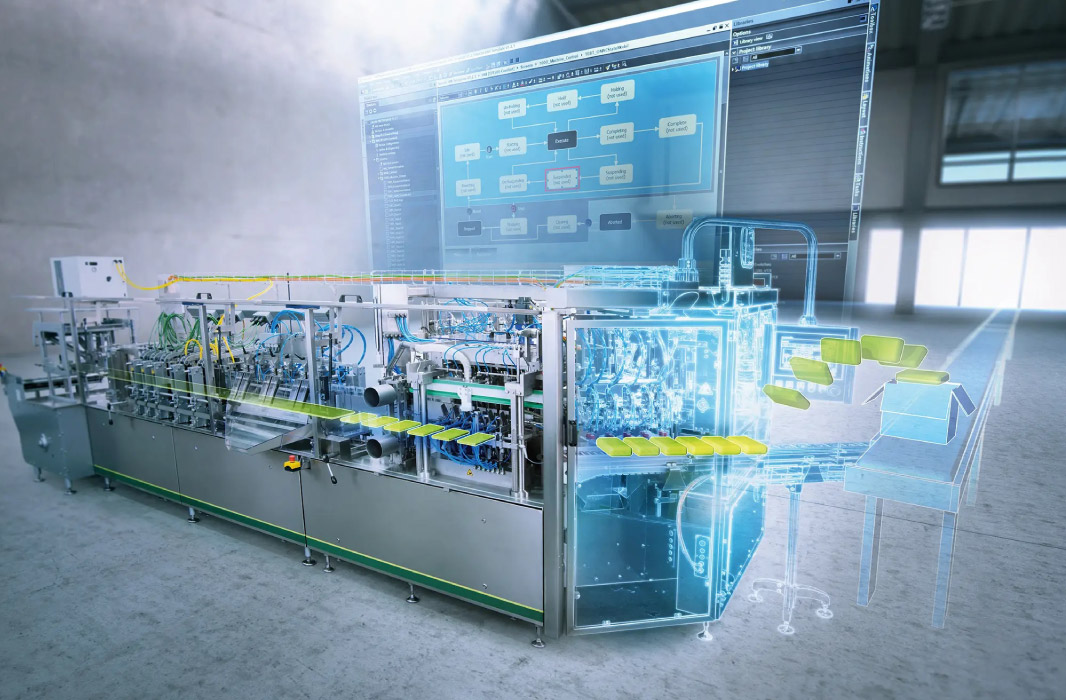

The onset of the fourth industrial revolution marks a pivotal shift in the European manufacturing landscape, confronting a plethora of challenges spurred by rapid technological progress and changing global circumstances. These include shorter product lifecycles, fluctuating demand, and an increase in product variants, necessitating a transformation in the industry’s paradigm. This transformation is characterized by the digital factory era, where intelligent, interconnected “cyber-physical systems” foster seamless communication and cooperation between people, machines, logistics systems, and products, optimizing processes through advanced information technology (IT).

Historically, the manufacturing industry’s business model has heavily relied on capital expenditure (CAPEX) on production equipment. This approach, however, has led to lower automation levels and increased labor requirements, contributing to competitiveness deficits due to low productivity. Such productivity challenges stem from inefficient use of production equipment, characterized by substantial losses during product family changes, minor breakdowns, adjustments, and quality issues.

Embracing Modular, Flexible, and Scalable Solutions

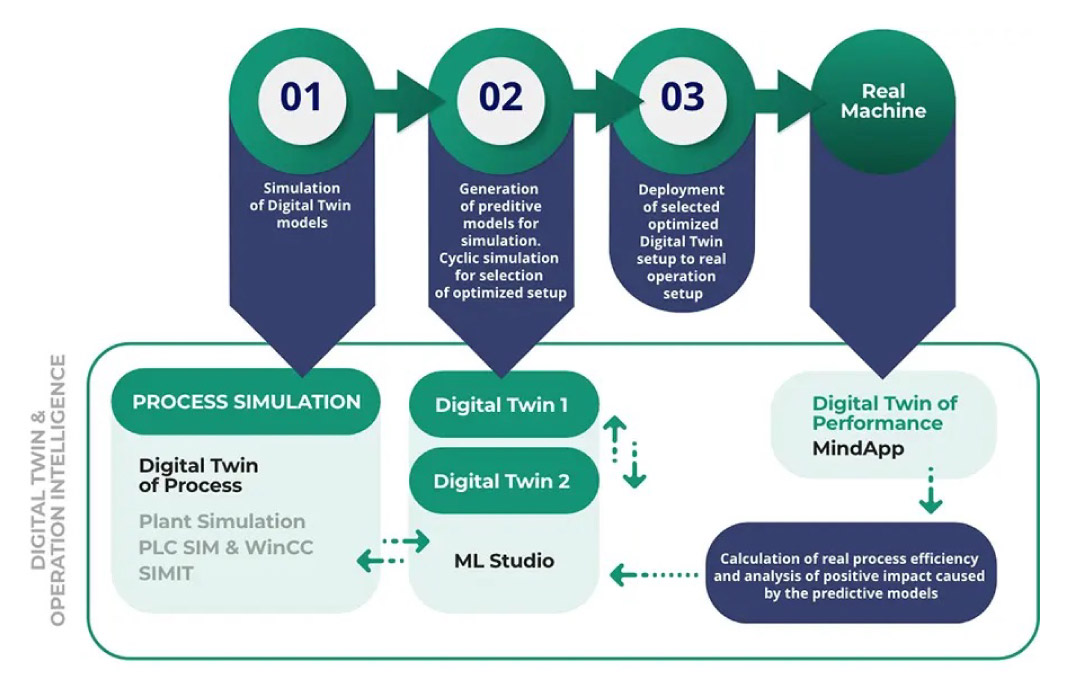

The concept of a Digital Twin emerges as a beacon for modern manufacturing, advocating for modular, flexible, and scalable frameworks. This concept integrates various platform modules across product and process lifecycles, embodying the principles of safety, quality, flexibility, and efficiency. It addresses the urgent need for manufacturing systems that can adapt to a market characterized by greater variability and the demand for customized products in smaller quantities.

Adapting to Mass Customization Trends

The trend towards mass customization, where consumers expect a wide array of components or accessories for their products, underscores the need for High Mix – Low Volume (HMLV) production environments. These environments, supported by Make to Order (MTO) / Build to Order (BTO) strategies, rely on process flexibility, product flexibility, and volume flexibility to meet unpredictable orders and cater to customer-specific needs.

Leveraging Operation Intelligence for Modern Processes

The application of Operation Intelligence provides a layer of real-time data visibility, enabling better operational decisions through continuously updated analytics on aggregated & contextualized process data. This shift from Business Intelligence to Operation Intelligence facilitates predictive operations and cost-effective maintenance services, reducing the impact of unforeseen process deviations.

Innovating with IIoT Cloud Platforms

The optimization of processes and predictive maintenance, based on data analysis and machine learning algorithms, necessitates a platform that aggregates necessary data to apply effective algorithms. Utilizing an IoT operating system, such as Mindsphere, processes applications for calculating Overall Equipment Effectiveness (OEE) indicators and ensures data reliability and security, enhancing strategic maintenance decisions and production forecasting.

Industry 4.0 heralds a transformative era for manufacturing, emphasizing the need for advanced technologies, flexible manufacturing systems, and intelligent data analysis to navigate contemporary challenges and elevate operational efficiency and competitiveness.

Our expertise:

- Digital Factory Implementation

- Scalable Production Frameworks

- Mass Customization Strategies

- High Mix – Low Volume Production

- Operation Intelligence Application

- Predictive Maintenance

- IIoT Cloud Platform Utilization

- Overall Equipment Effectiveness Analysis

Want to know more about this service?