solutions

CNC Tending Portfolio

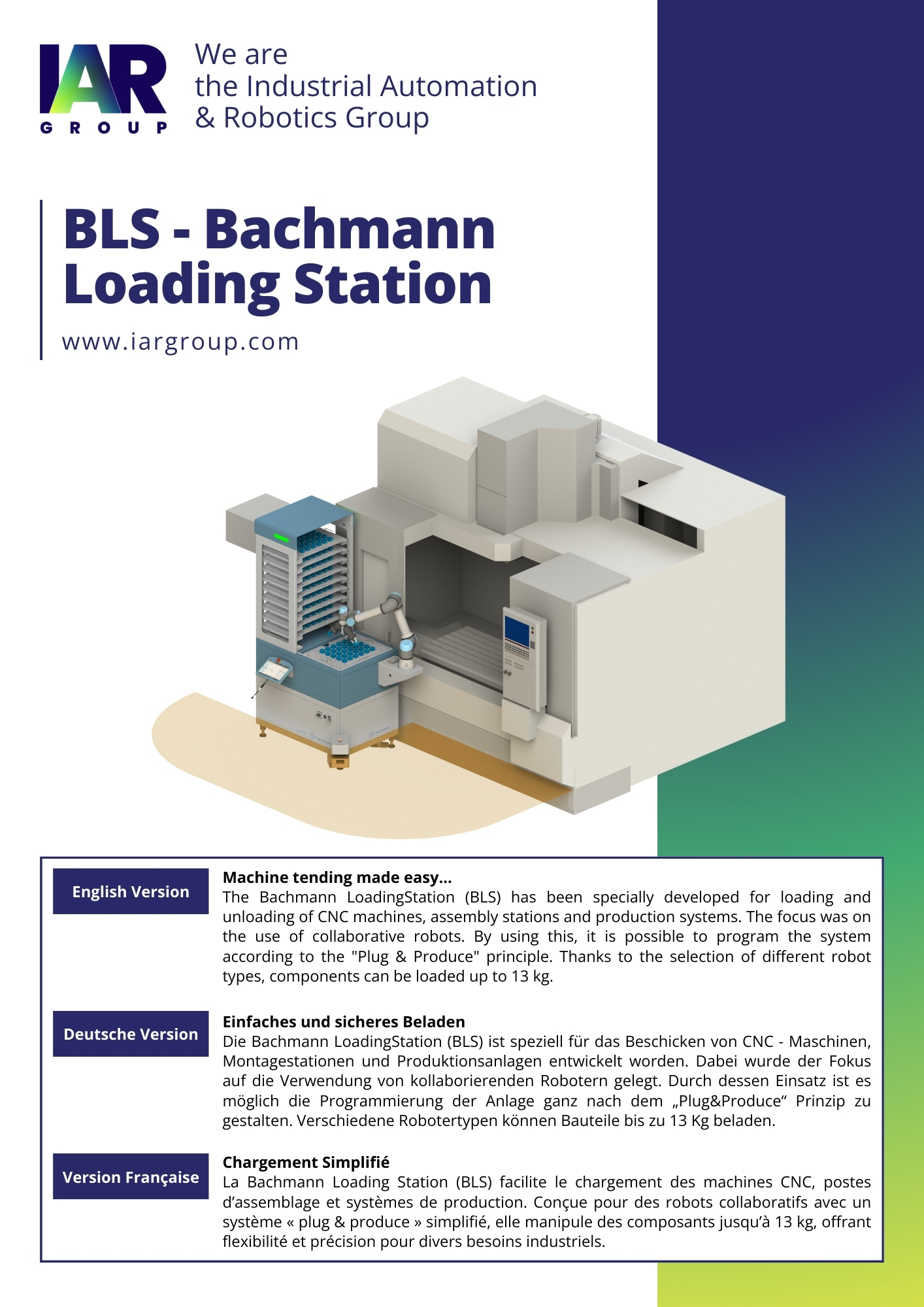

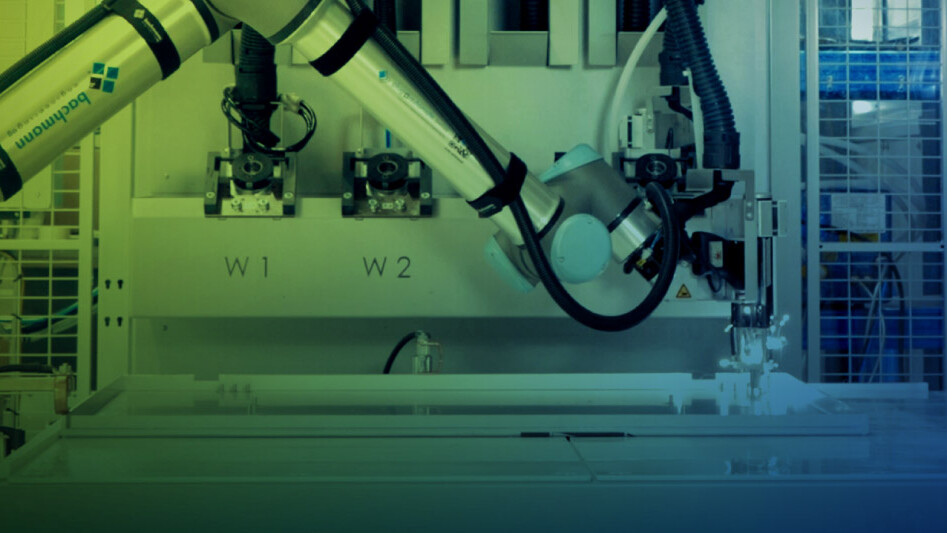

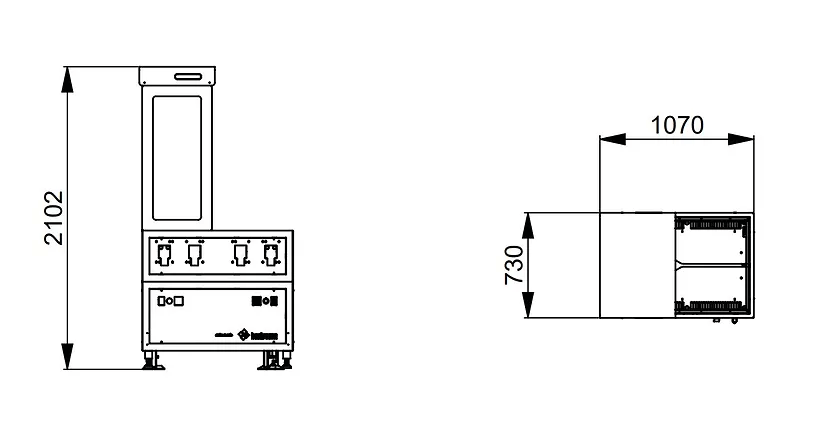

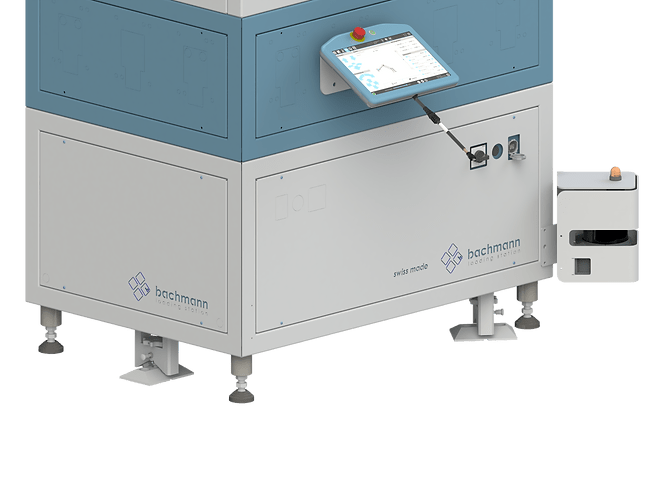

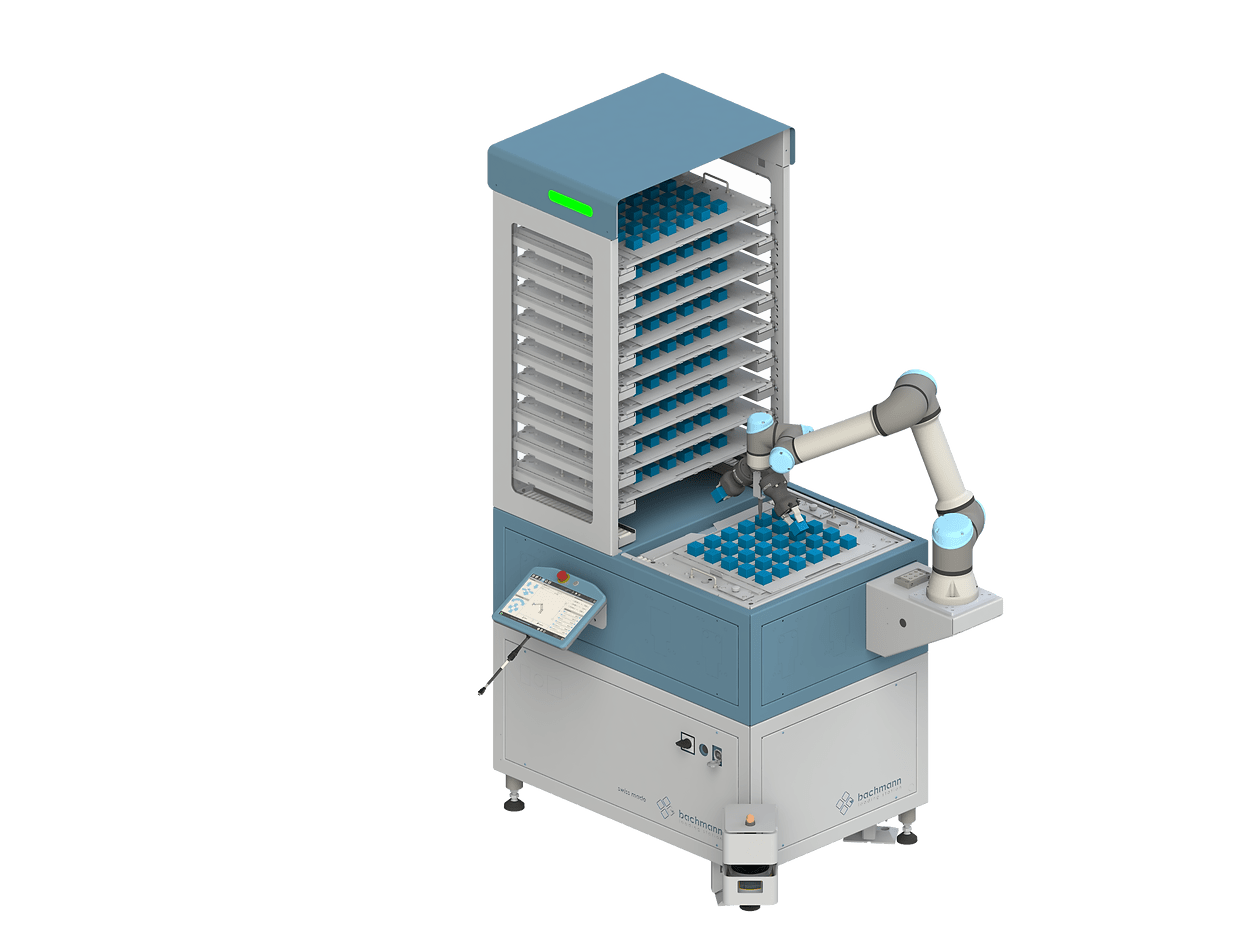

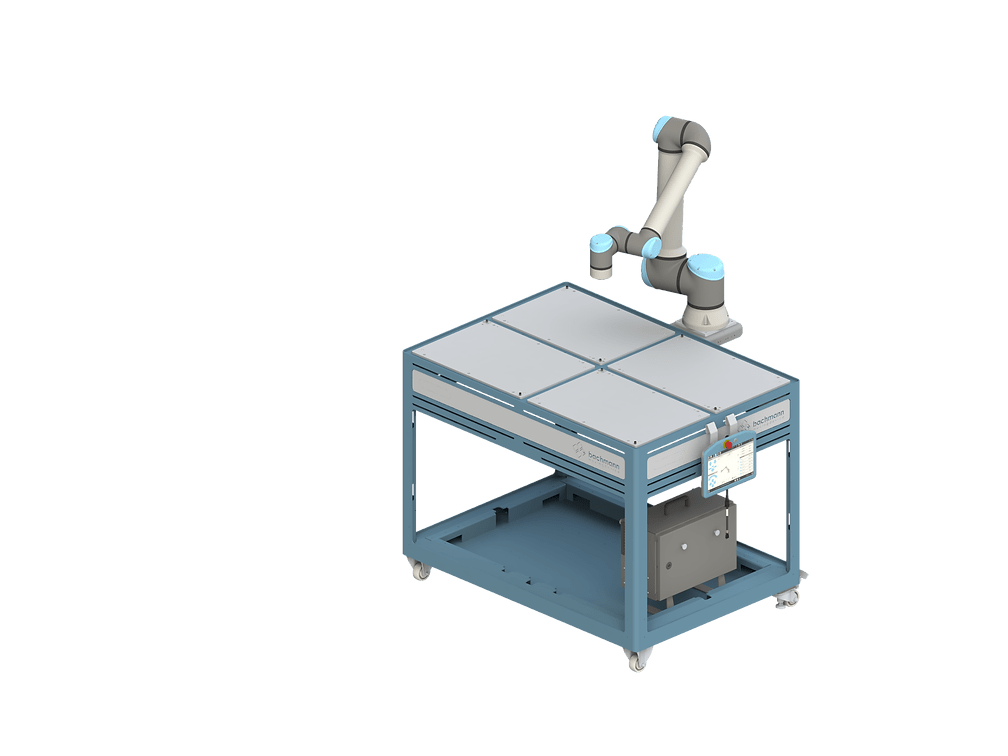

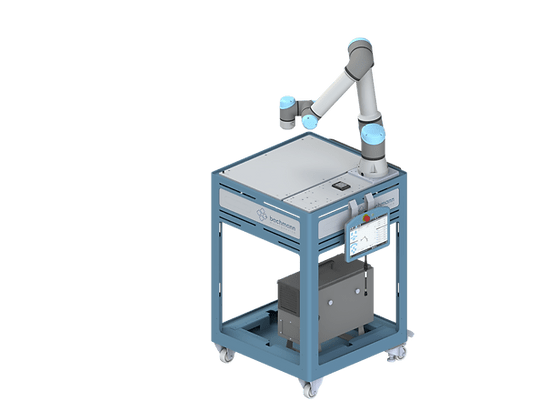

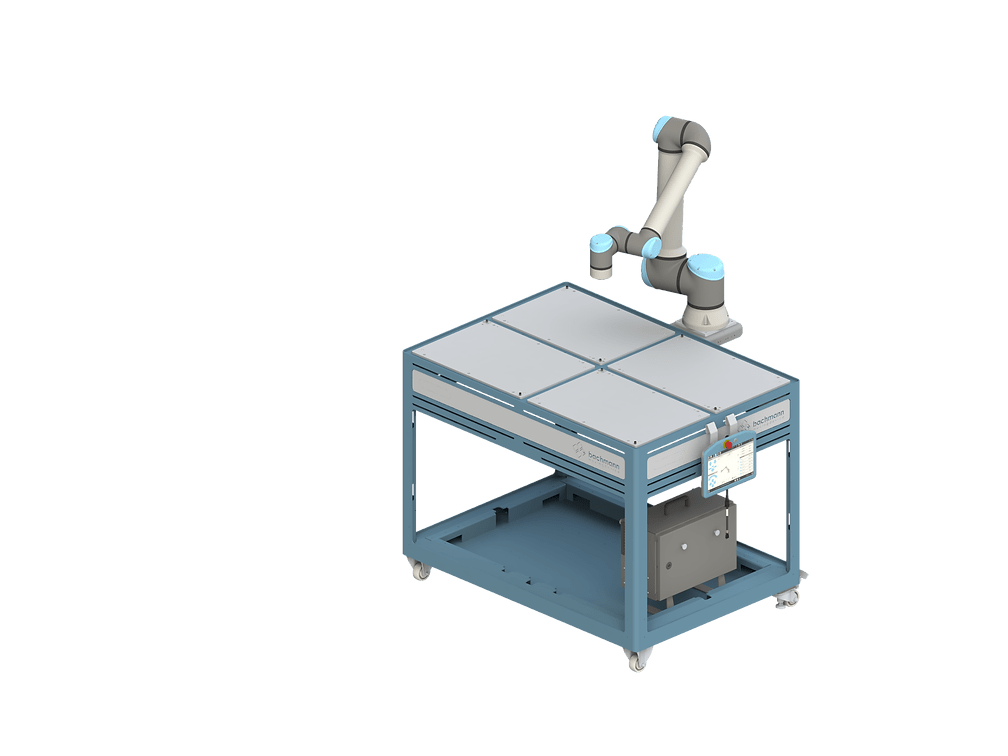

Bachmann Loading Station BLS

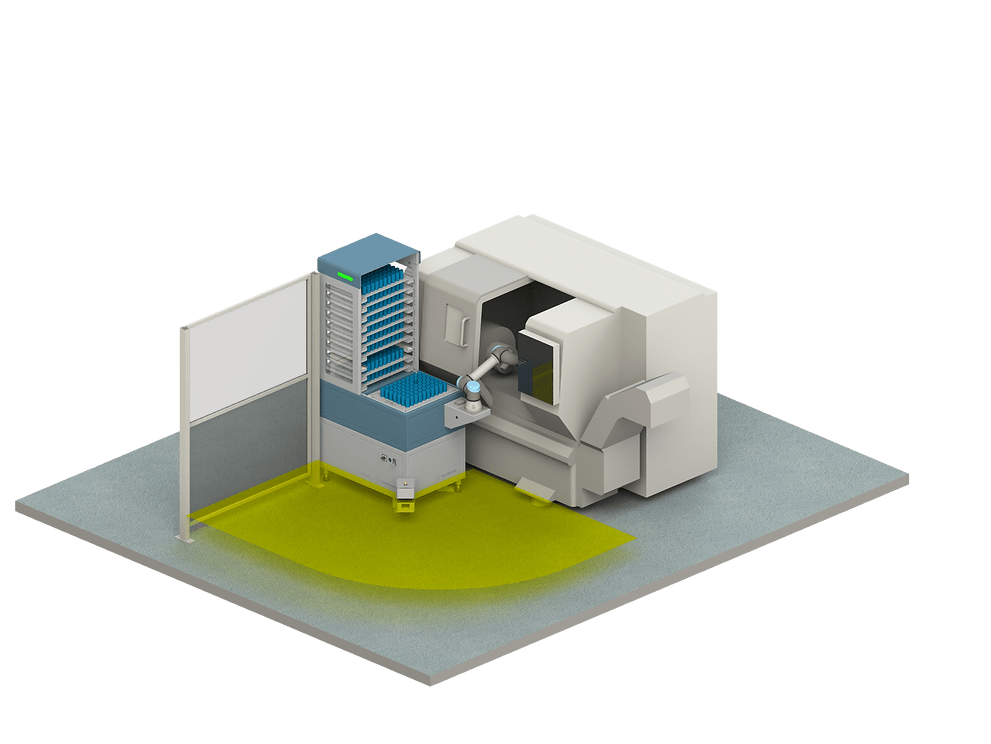

Operation Area

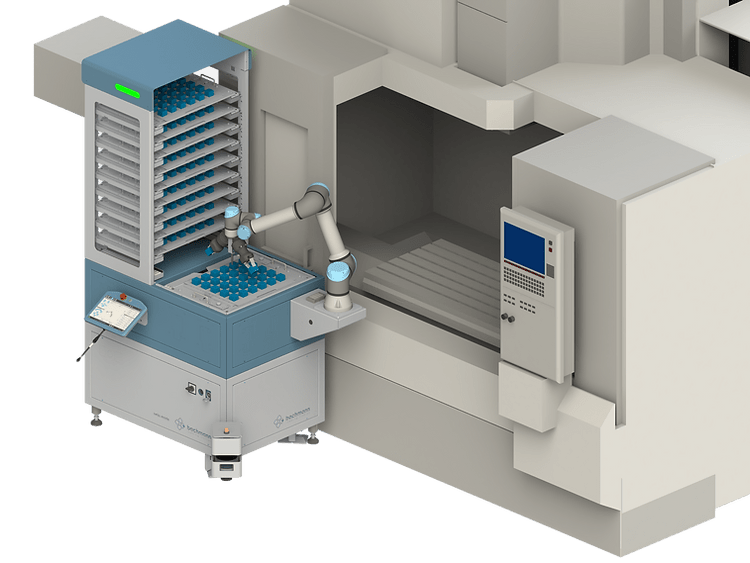

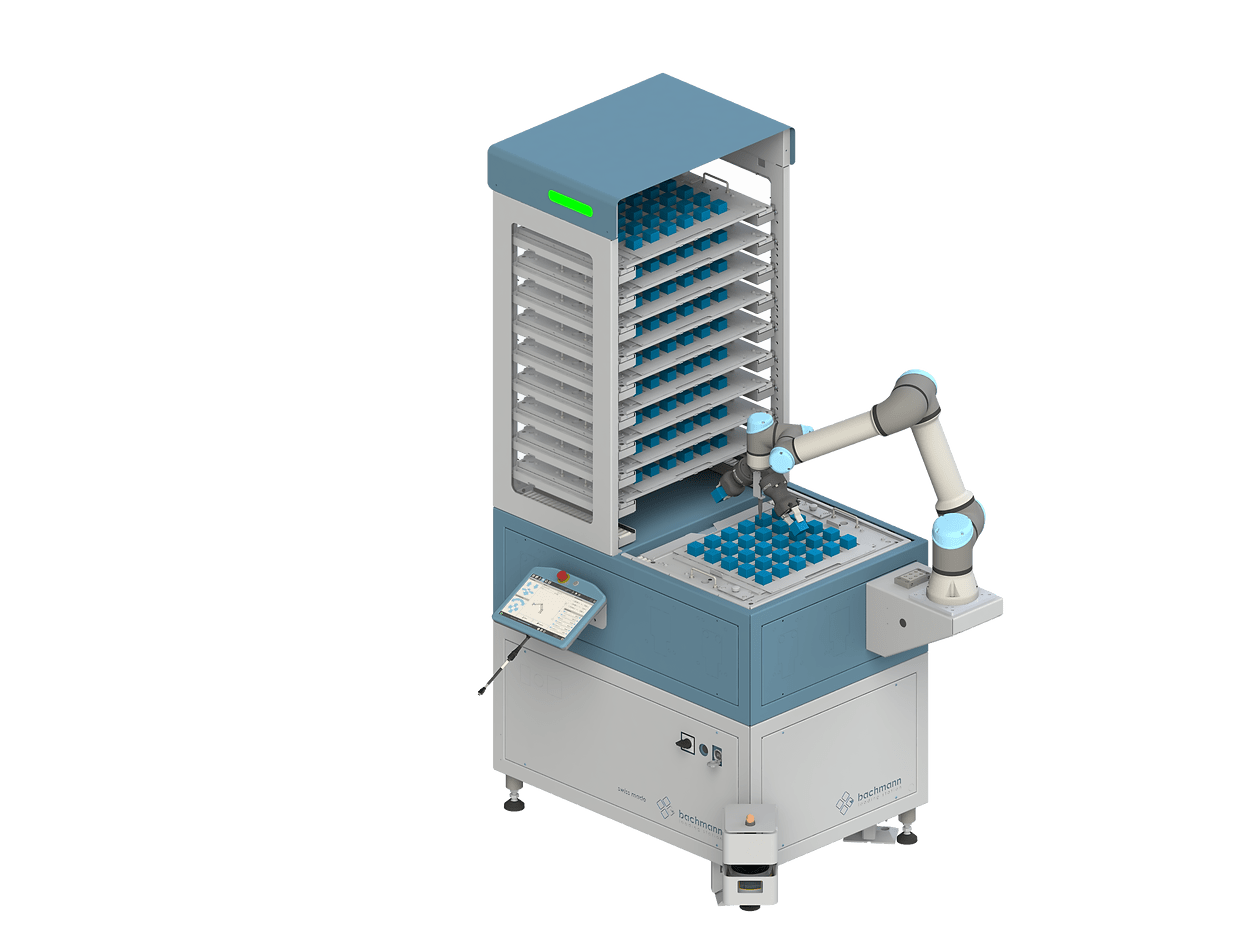

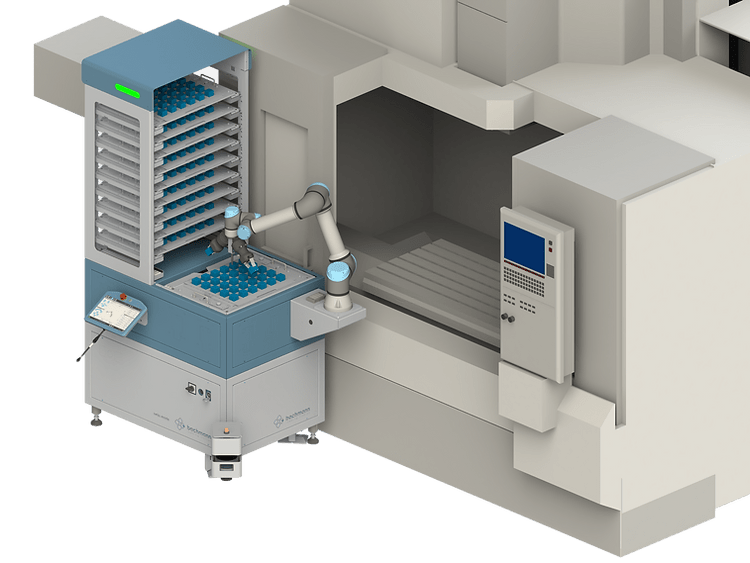

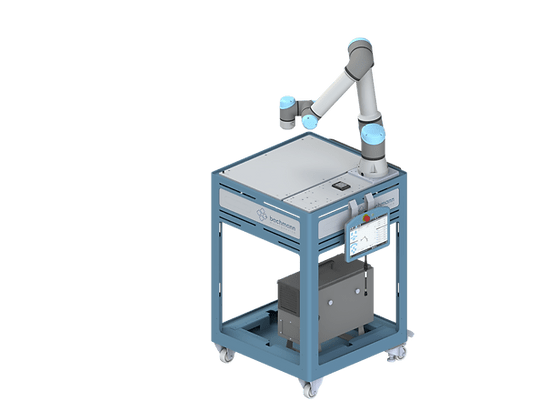

The Bachmann LoadingStation (BLS) has been specially developed for loading CNC machines, assembly stations and production systems. The focus was on the use of collaborative robots. By using this, it is possible to program the system according to the “Plug & Produce” principle. Thanks to the selection of different robot types, components can be loaded up to 13 kg.

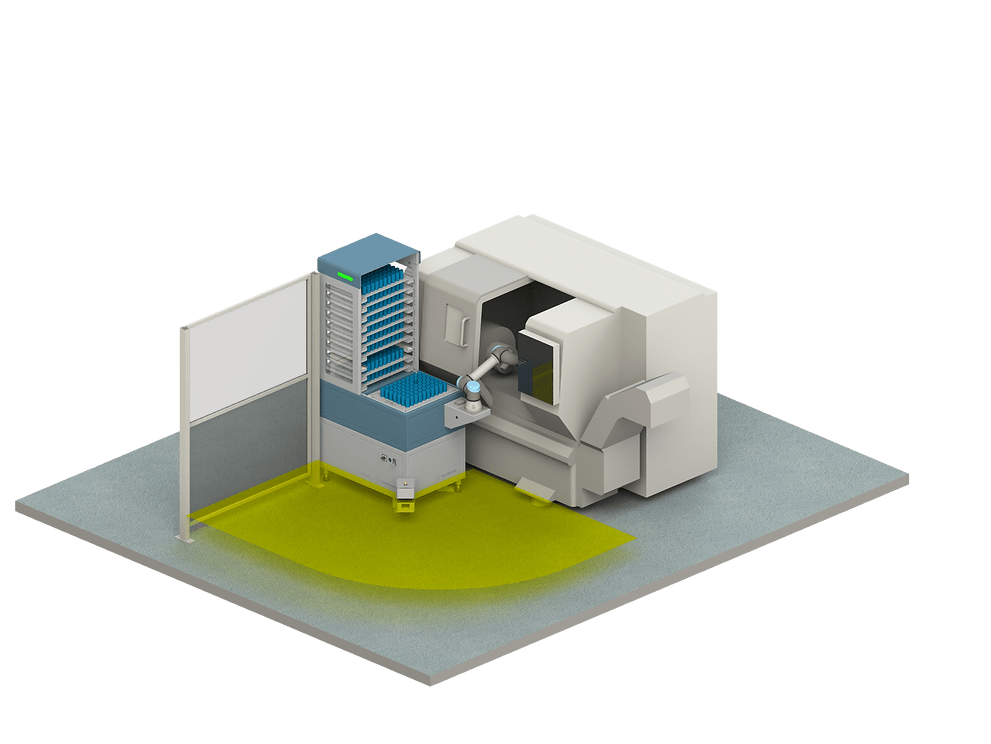

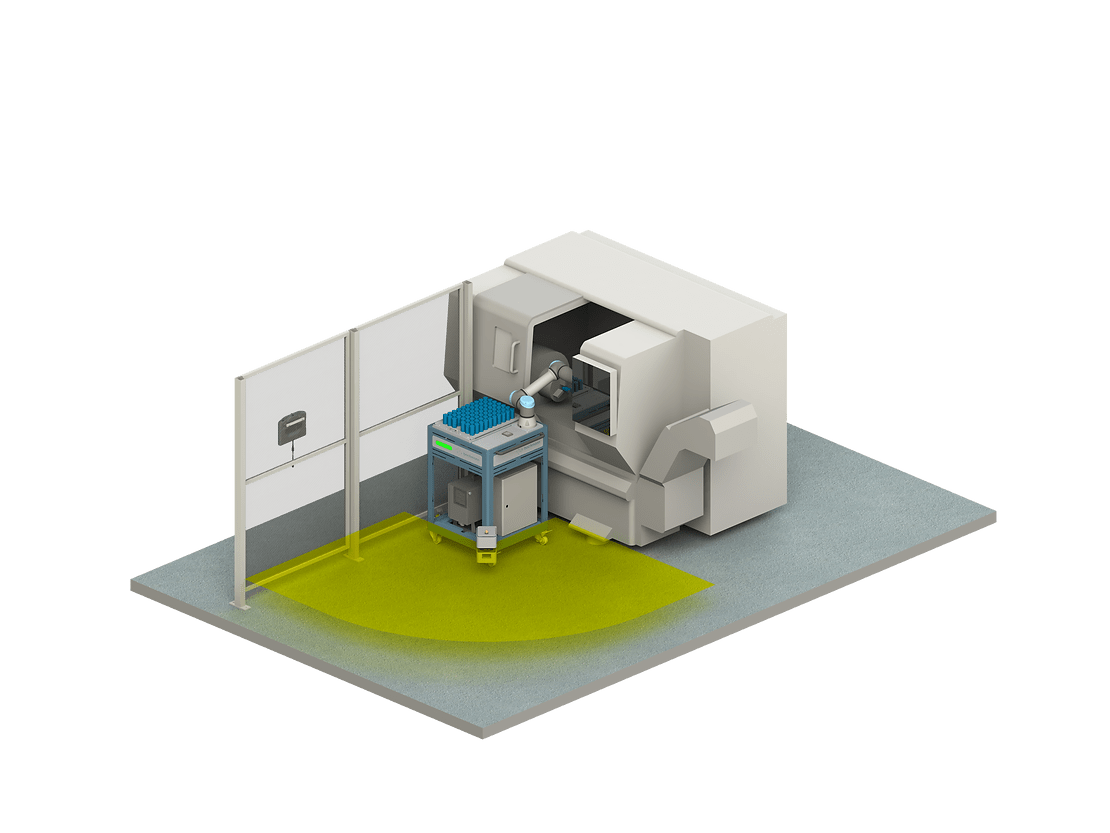

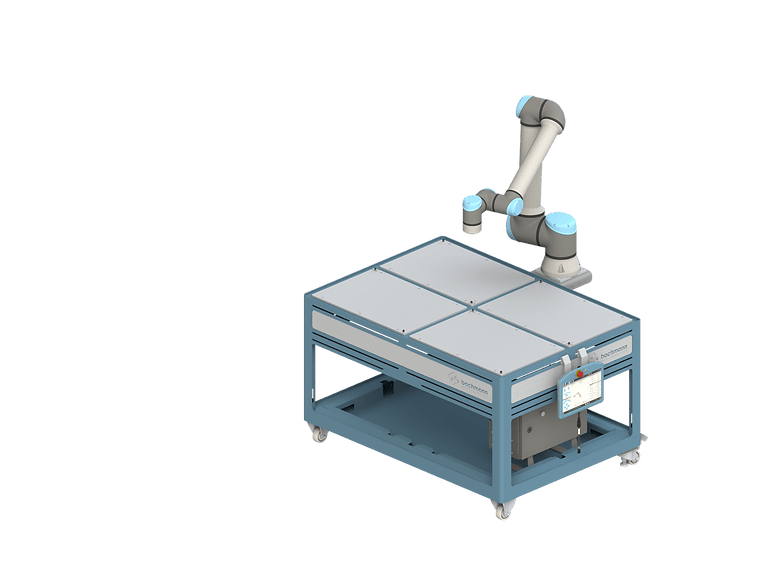

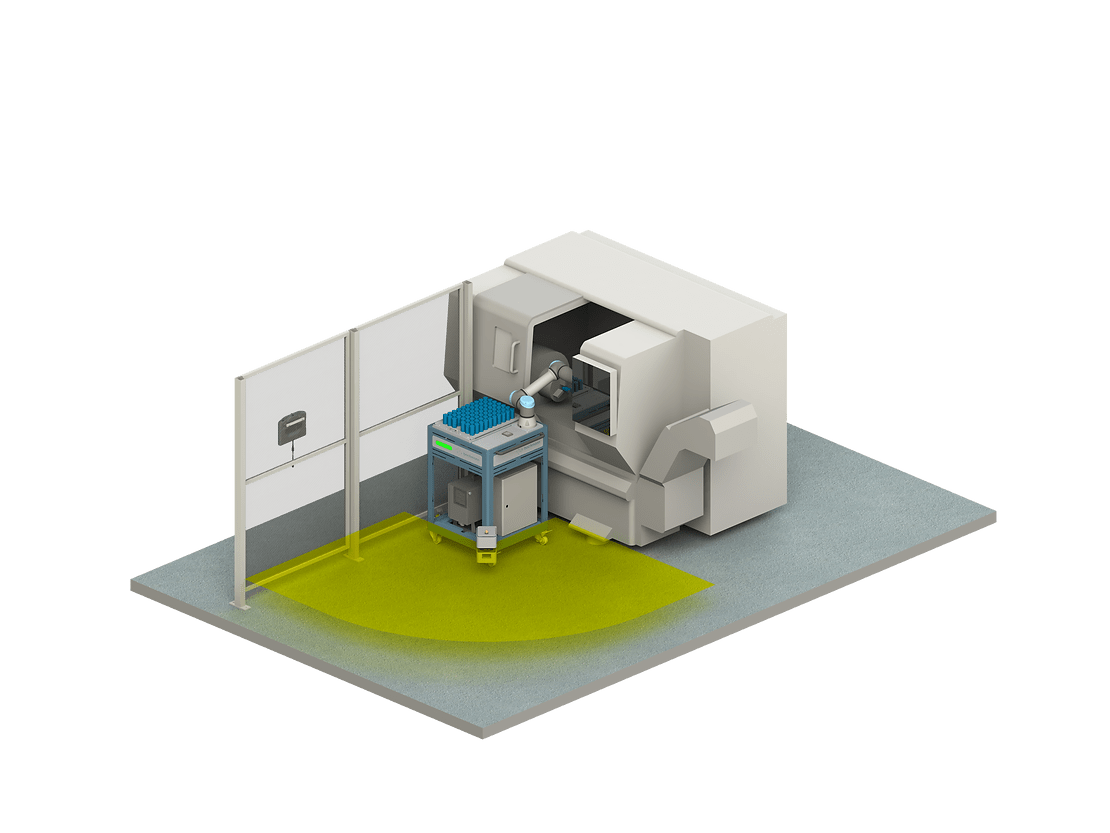

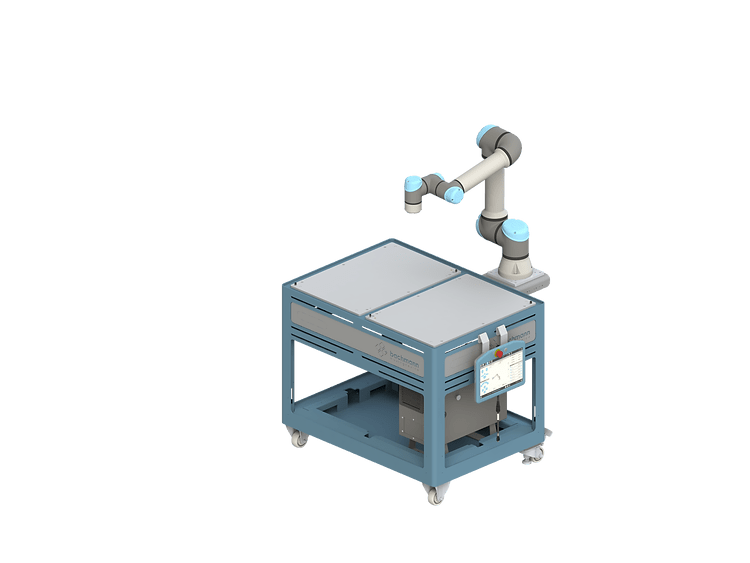

Open Shelter Cell

Thanks to the combination of the most modern safety components and the use of collaborating robots, the protective cell can be kept open on the machine side. This arrangement enables almost unrestricted access to the machine and also allows brief inspection views during the work process.

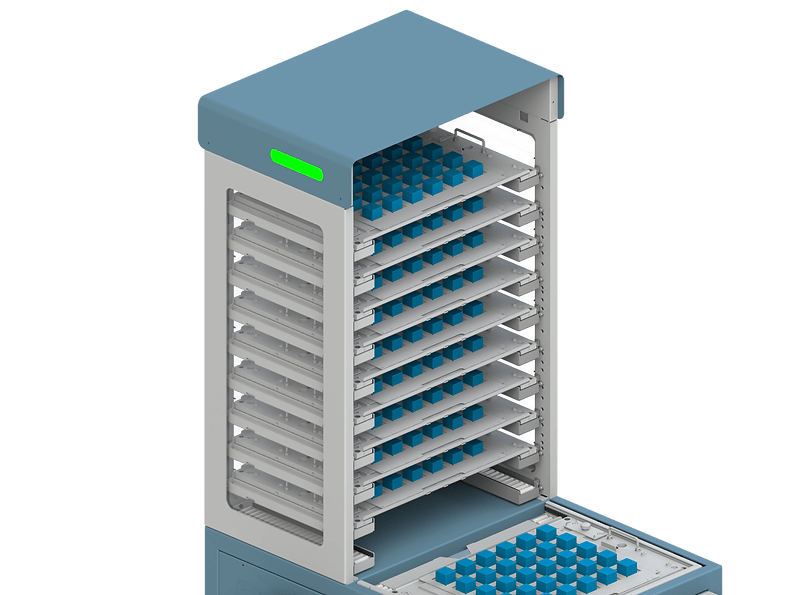

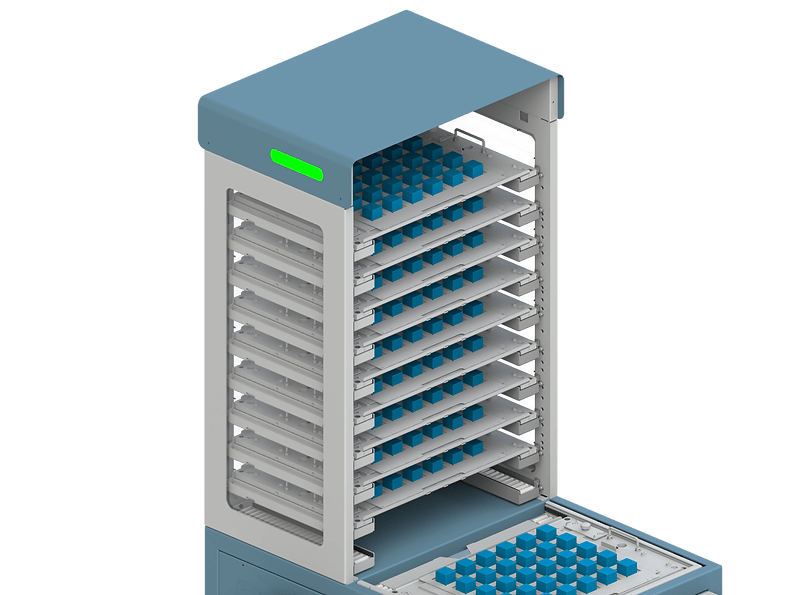

Compact Autonomy

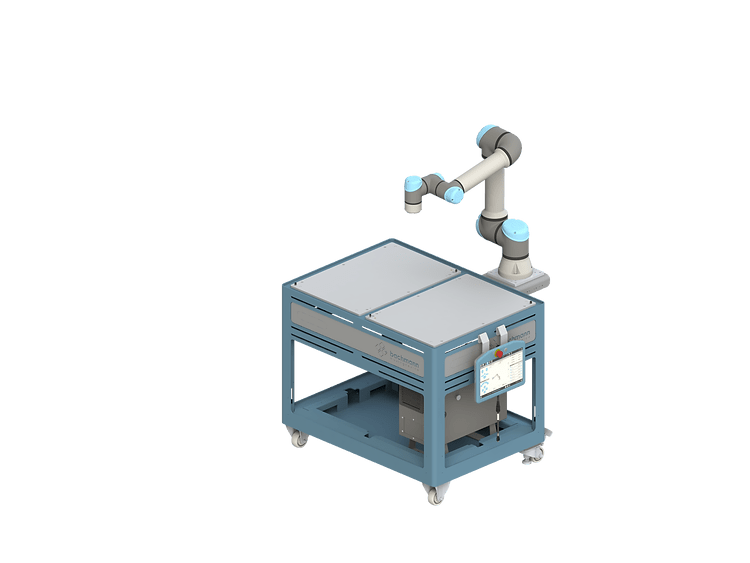

The BLS module has a maximum of 10 ¼ EUR pallet spaces which can hold the workpieces/products. The division can be flexibly selected from 3 to 10 levels. Thus, a storage area of 2.5 EUR pallets is accommodated in the smallest space. The pallet change takes place automatically.

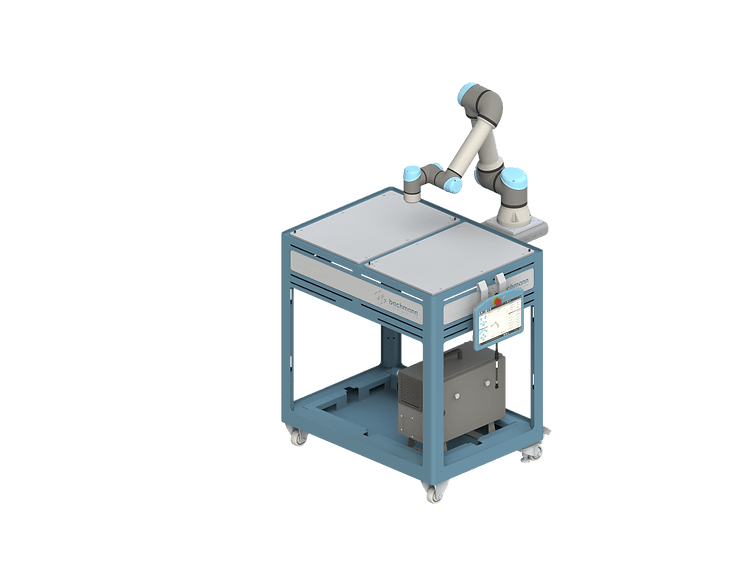

Mobility

Thanks to the BQL QuickLock coupling system from Bachmann Engineering, it is possible to move the system within a short time. Thanks to the self-centering systems, the system can be positioned exactly. This reduces the time required for conversion to a minimum.

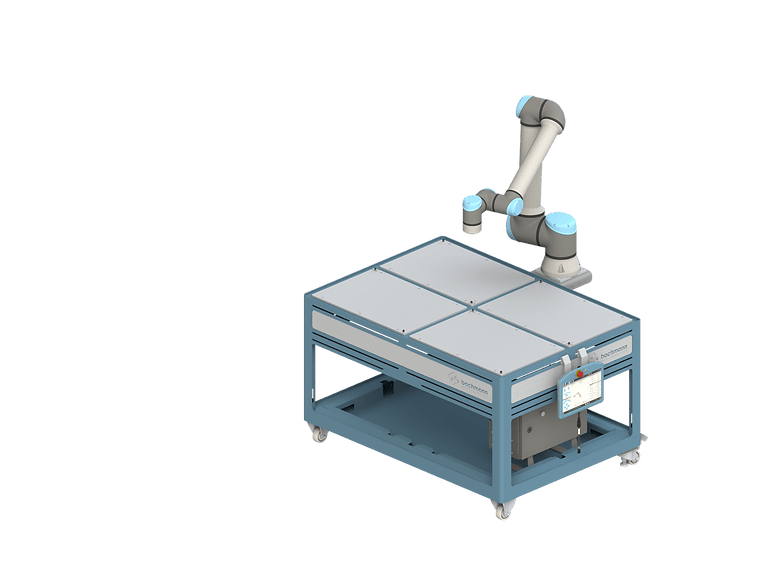

The BLS is a modular unit that can be adapted to the needs of the customer. The variety of adjustment and positioning options guarantees that the system is always set up in a space-optimized manner. The BLS can be equipped with different robot types.

In the BLS, care was taken to use standardized and field-tested standard components as far as possible. When it comes to robots, it relies on the number 1 in the world of collaborative robots, Universal Robots.

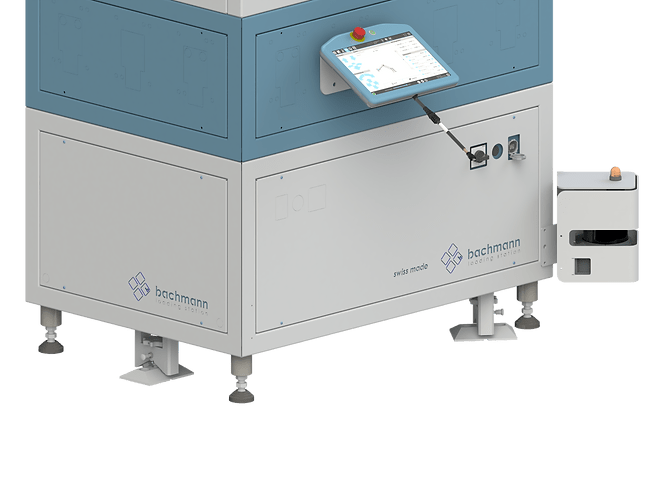

The BLS can be easily controlled using the included UR Cap software plugin. The control was deliberately designed to be very intuitive so that even untrained personnel can operate the system. In addition to a Quick Control interface, which allows the system to be conveniently controlled for loading and unloading, a large number of parameters can be set in the advanced settings of the UR Cap, so that, for example, the division of the pallet storage can be adapted by the customer to his needs.

Easy to use

Optimized for collaborative robots, Easy and safe loading, Simple and intuitive programming

Flexible and mobile

Innovative security concept, Multi-machine capable, Cell can be moved manually, Unrestricted access to the CNC machine

Compact structure

Extremely space-saving: space requirement of <1m2, High autonomy

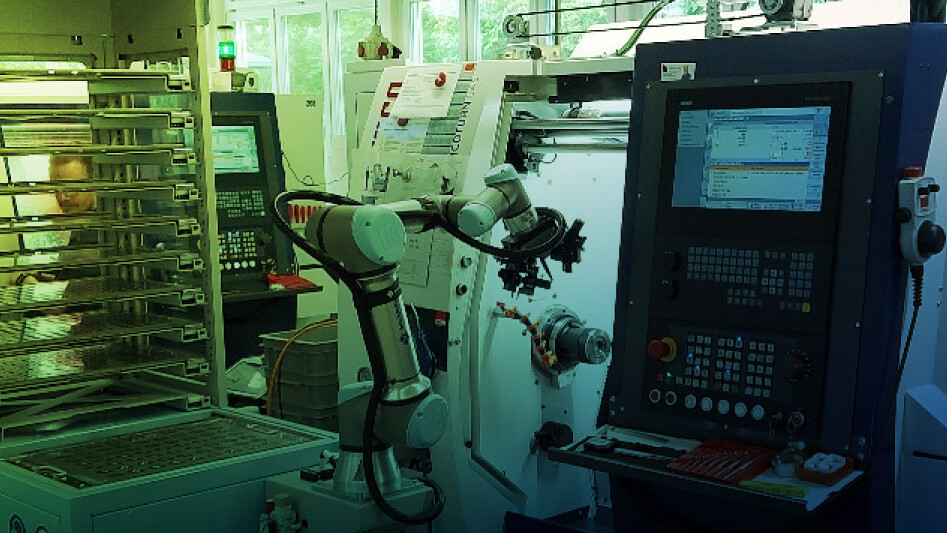

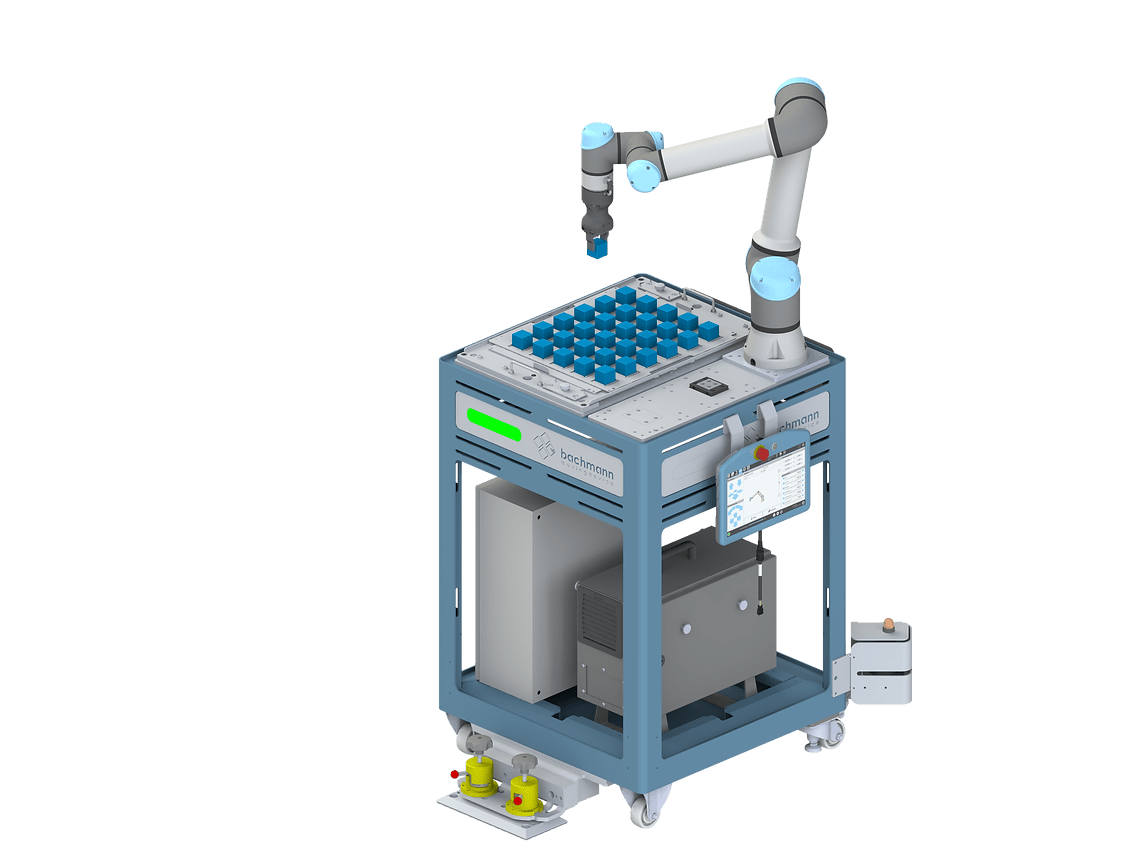

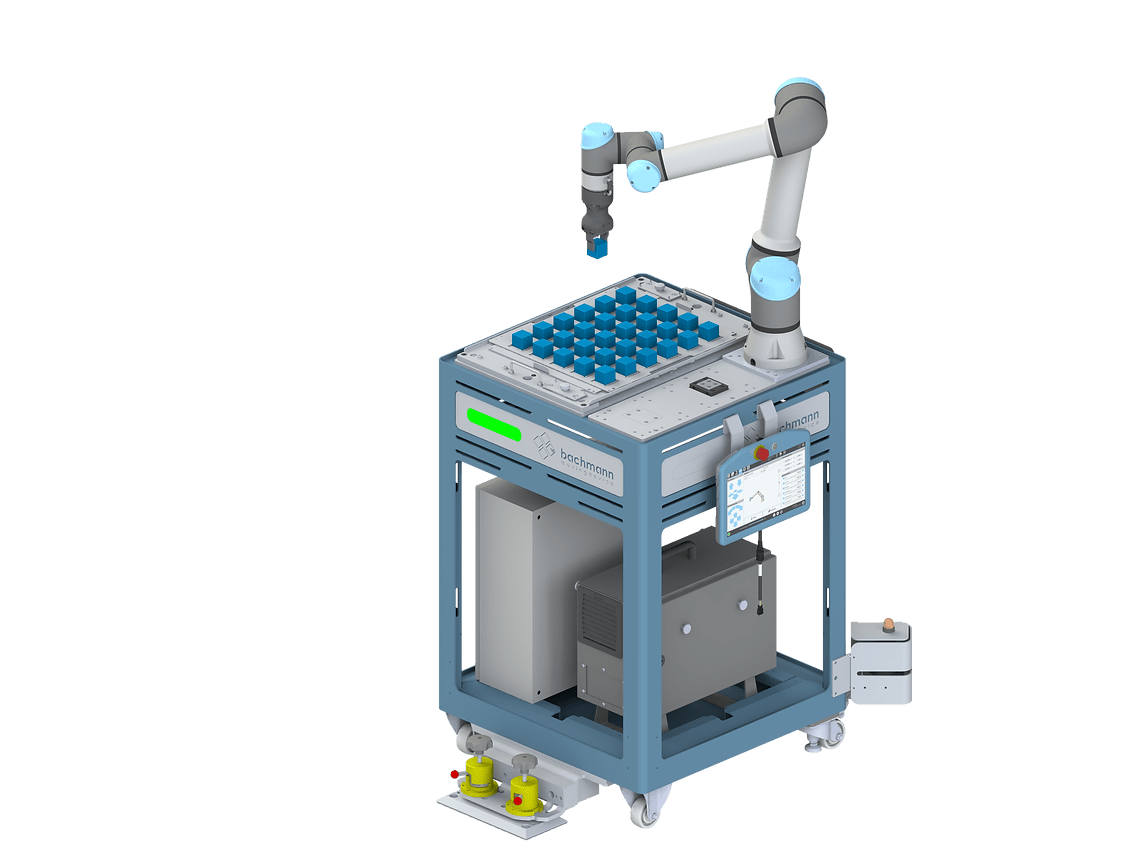

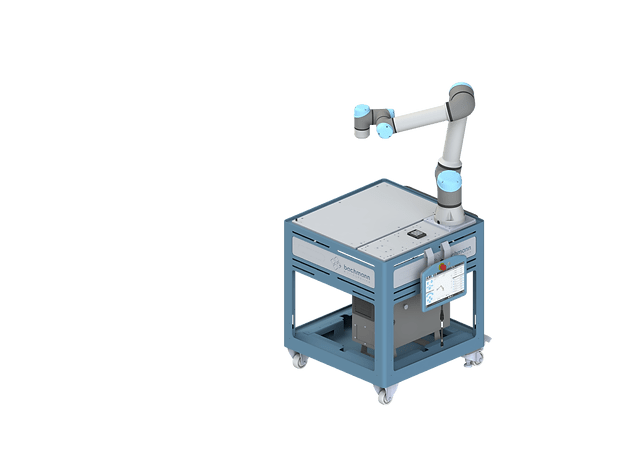

Bachmann Moving Device BMD

Little Need for Space

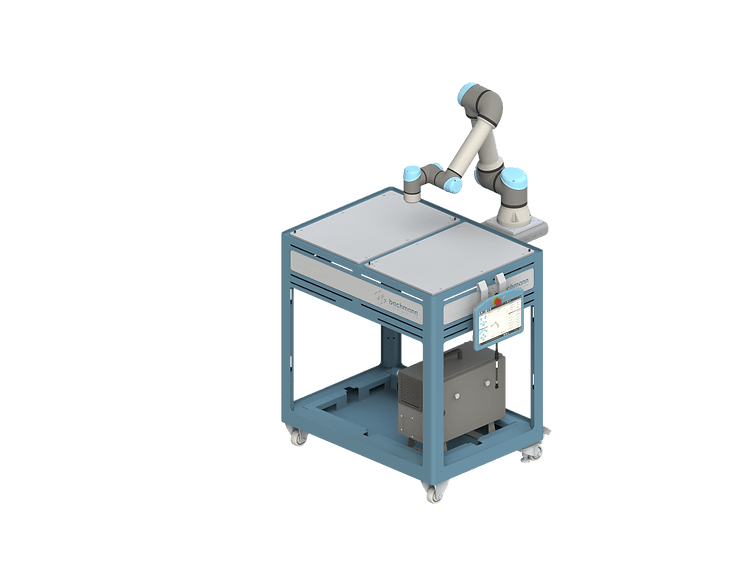

The Bachmann MovingDevice is characterized by its small space requirement of less than 0.5m2 and can be easily and quickly added to a manufacturing and assembly process or a laboratory application. The interfaces to the robot types UR3/ UR5 and UR10 are guaranteed; if required, other robots can also be implemented.

The robot control is integrated directly in the module. An additional control cabinet provides additional I/O if necessary. Cable bushings are used to easily feed signals directly to the robot.

Flexibility

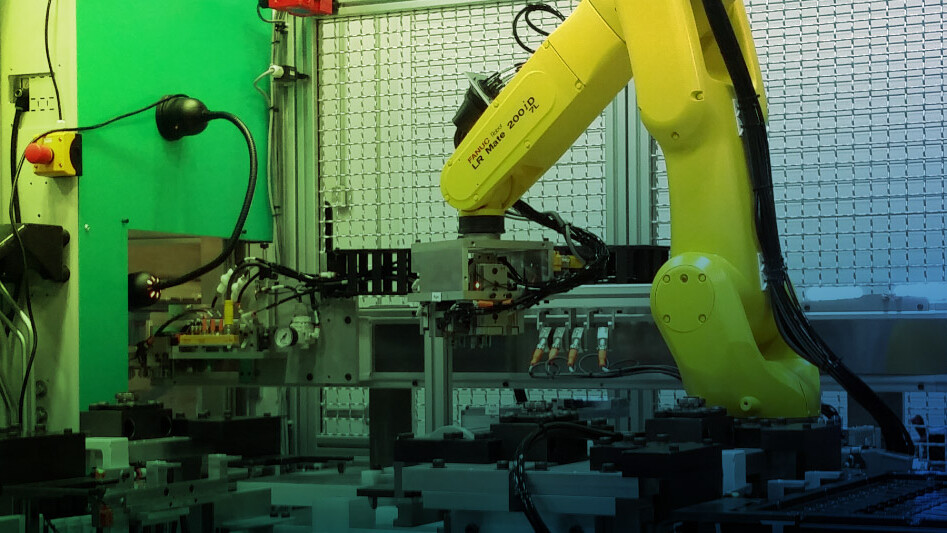

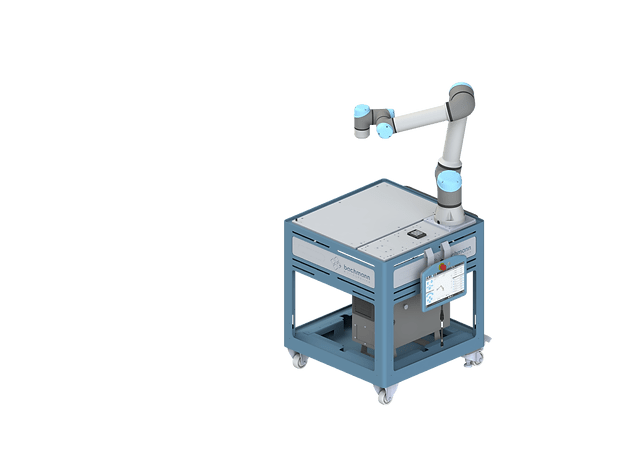

The Bachmann MovingDevice can be moved on rollers and is connected to the desired system in the exact position using standardized floor or machine coupling. Thanks to the multi-machine concept, the BMD can be positioned on different systems.

Modularity

The Bachmann MovingDevice has a modular structure and can be configured according to individual requirements. Indicator lights on all sides are used to display the status. The scanner ensures extended personal and process safety. A drip tray is integrated to prevent liquids from dripping off. A standardized machine interface is used for quick connection to your system.

Configurable

Can be customized to individual requirements

Economically

Footprint of less than 0.5m2

Mobile

Movable thanks to castors with standard coupling

Our expertise:

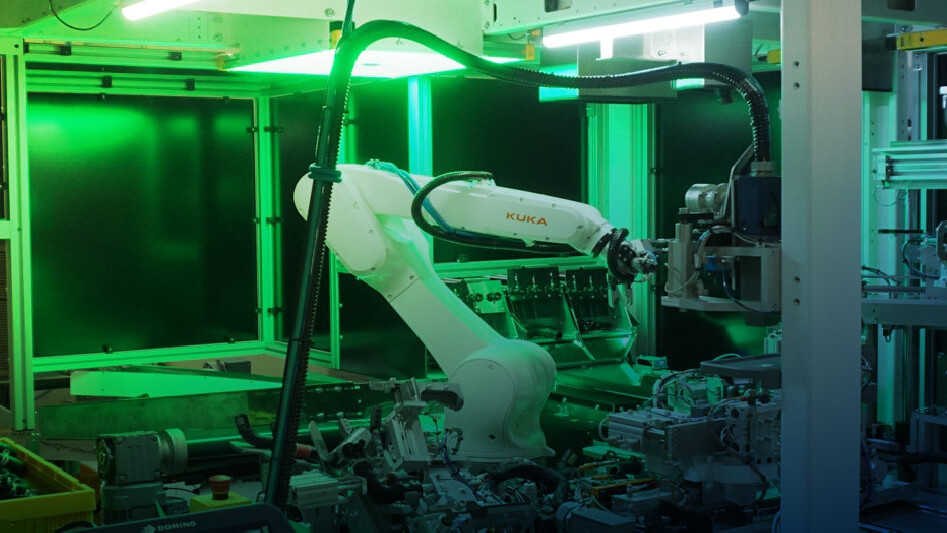

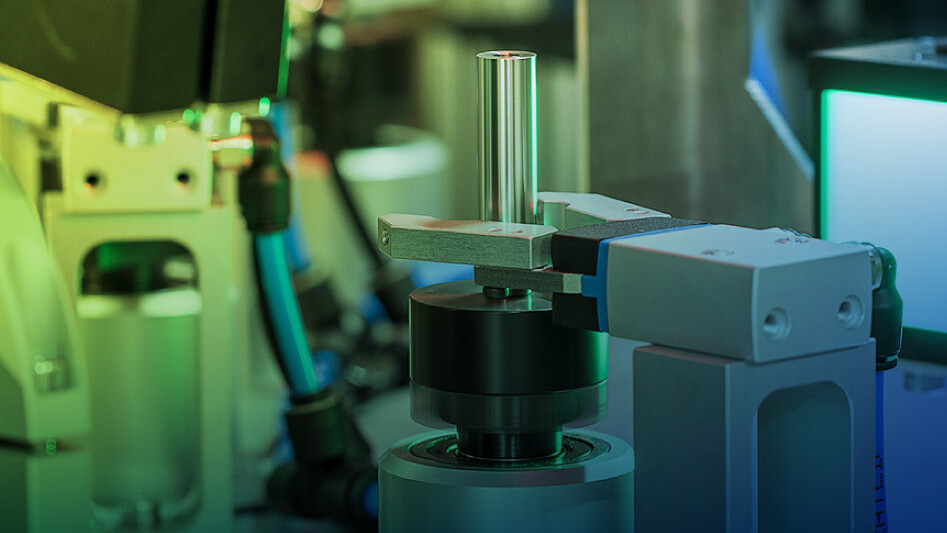

- CNC, assembly and manual workstations feeding systems

- CNC automatic loading and unloading

- Small footprint solutions

- Modular and portable devices