solutions

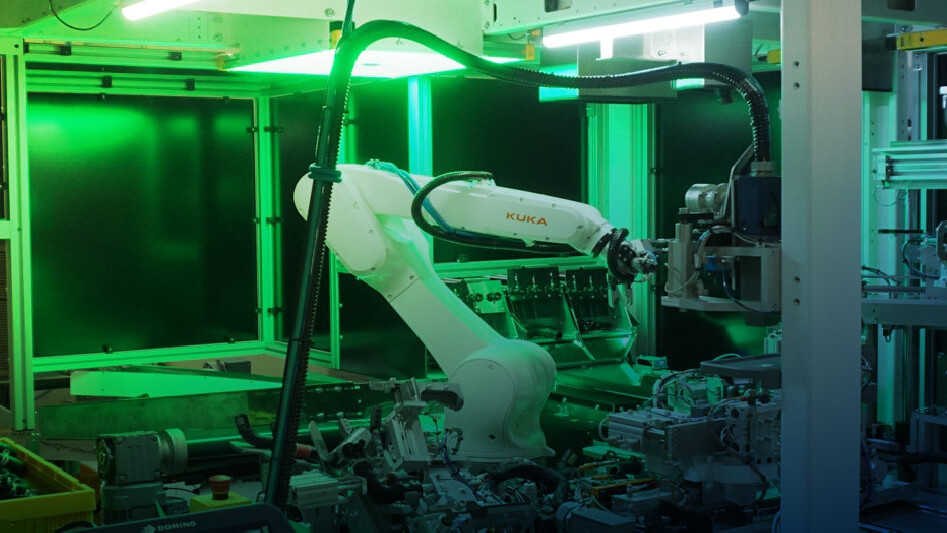

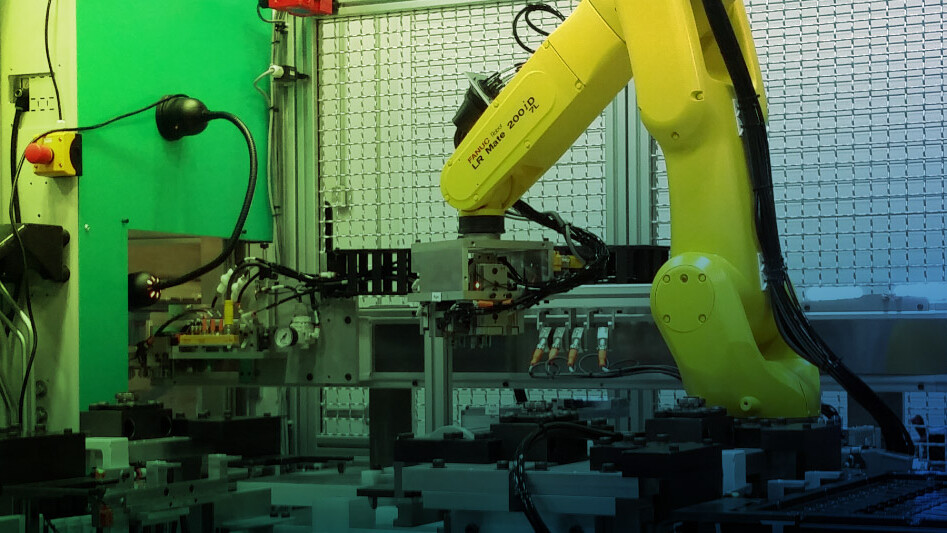

Automatic CNC Tending Robotics

Elevating Productivity with Precision and Safety

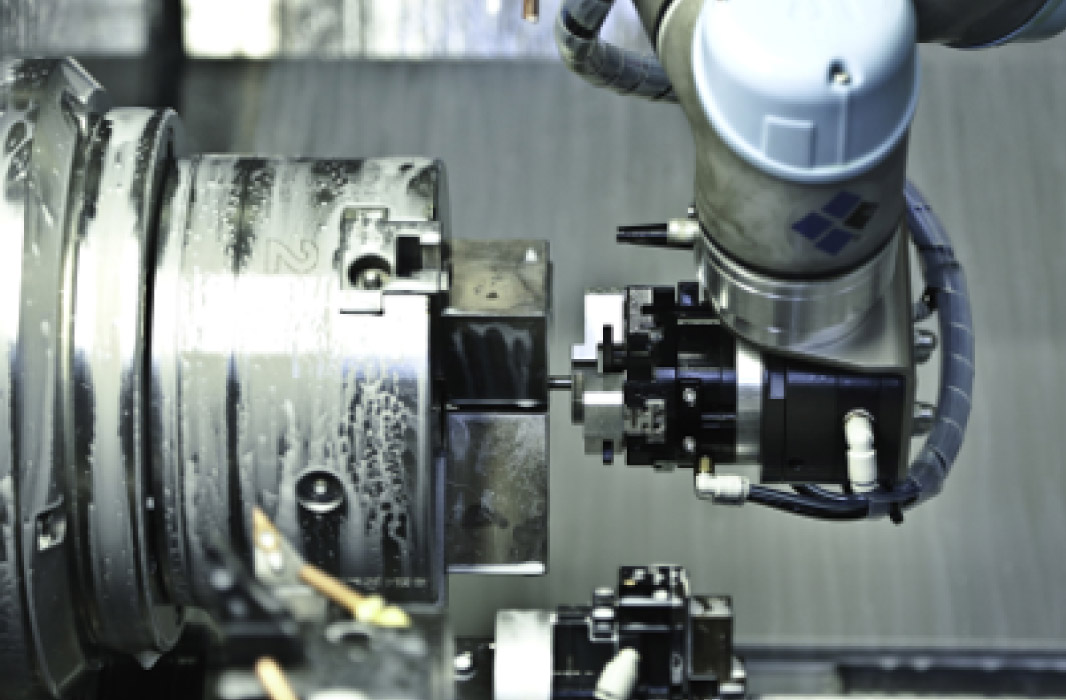

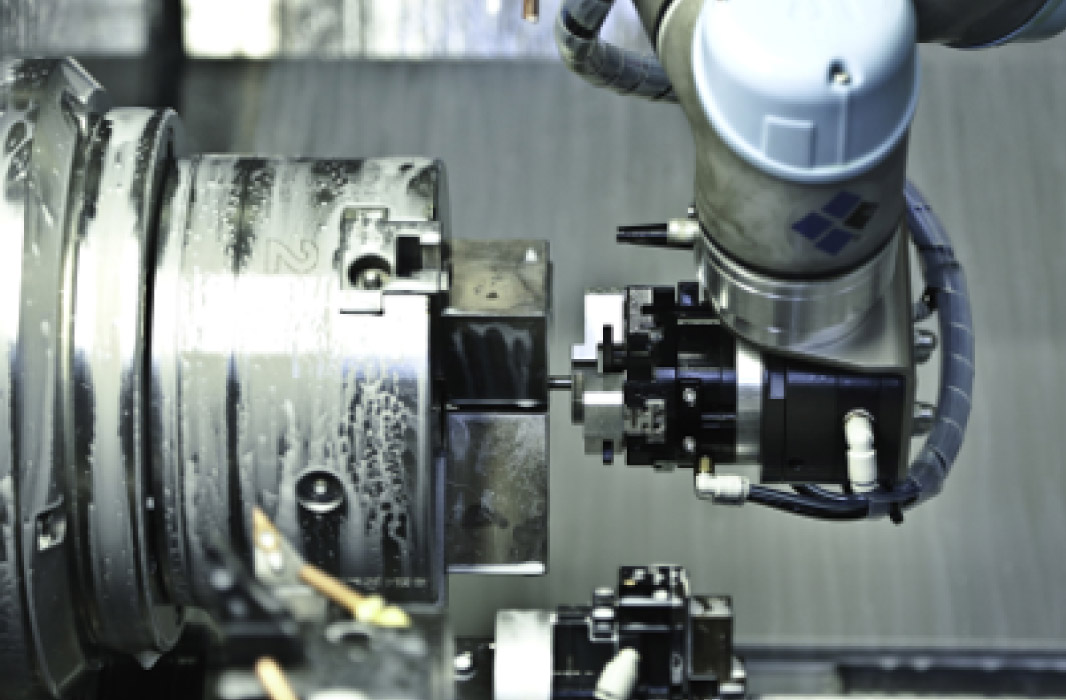

In the realm of CNC machining operations, achieving higher productivity without compromising safety is paramount. Robots excel in this environment, outperforming humans in executing repetitive tasks with unmatched speed and consistency. While CNC machines are central to the machining operations, they often require human operators for ancillary tasks, such as loading raw material and unloading finished parts. These tasks, though necessary, are repetitive, monotonous, and prone to human error, leading to potential work accidents and productivity losses.

Recognizing the limited value these tasks add to the machining process, we advocate for their automation through robotics. This not only enhances safety by reducing the risk of accidents but also significantly boosts productivity. By automating these monotonous tasks, operators are liberated to focus on more complex, value-added activities.

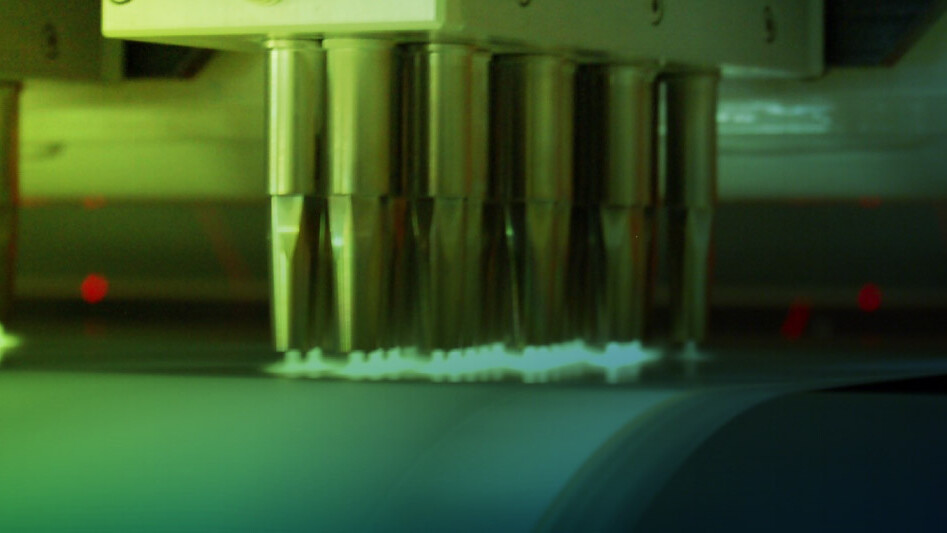

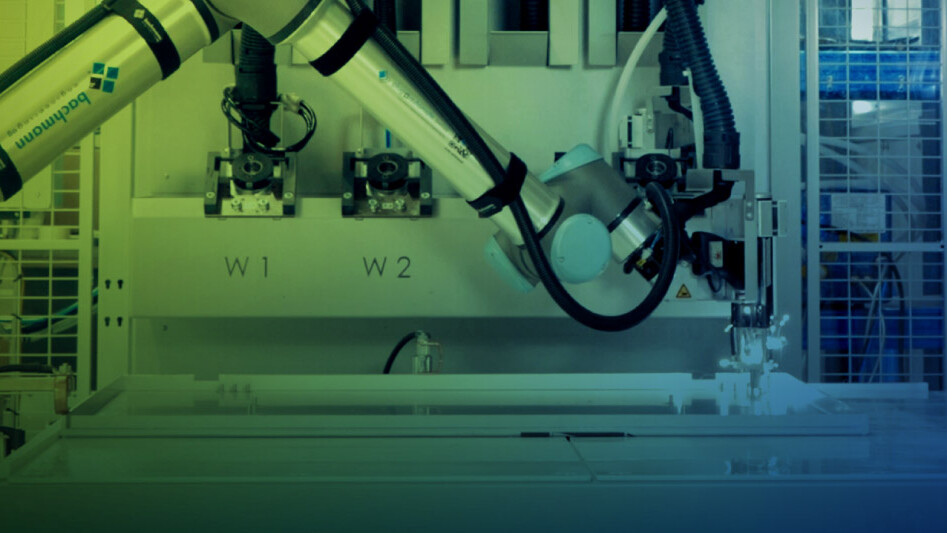

Introducing the LUS Product Line: a Swiss-designed, market-leading solution in robotic parts feeding and separation. Our LUS systems redefine efficiency in CNC tending, setting new standards in both productivity and safety.

Discover the future of CNC machining: www.lus-systems.com.

Our expertise:

- CNC, assembly and manual workstations feeding systems

- CNC automatic loading and unloading

- Small footprint solutions

- Modular and portable devices