Collaboration of Automation, Robotics, and Plasma Technology

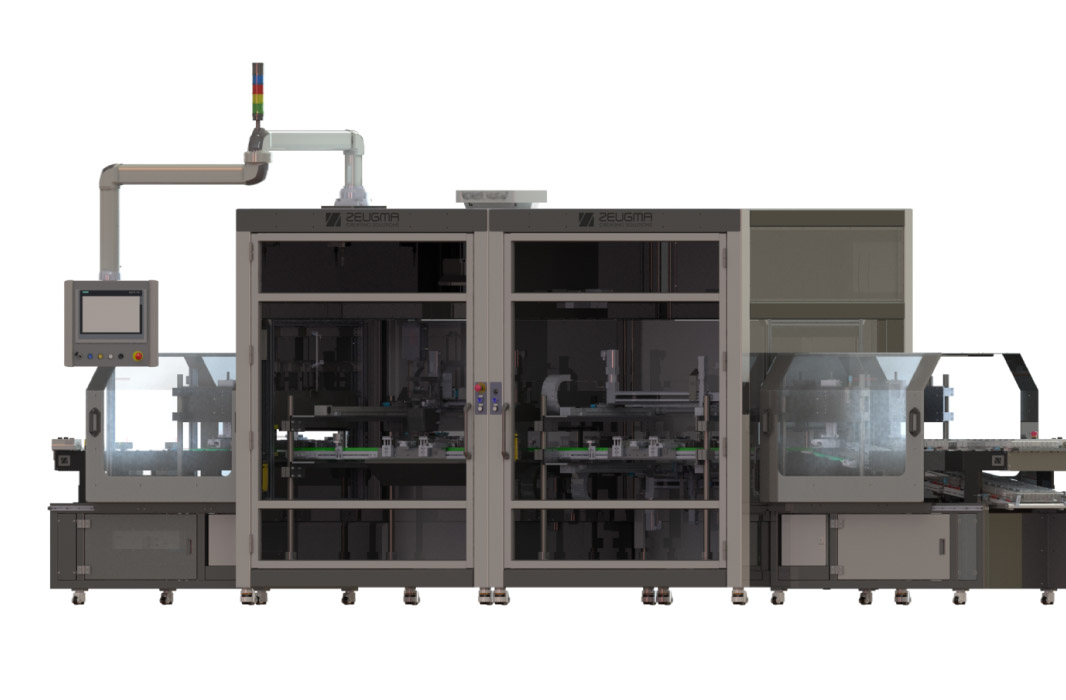

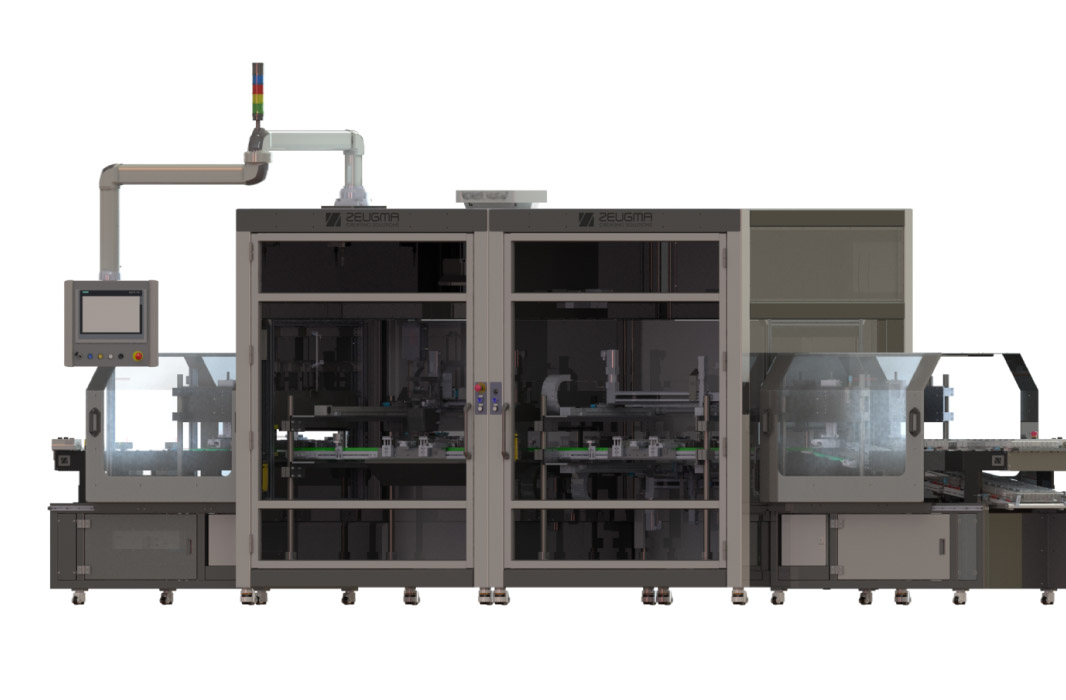

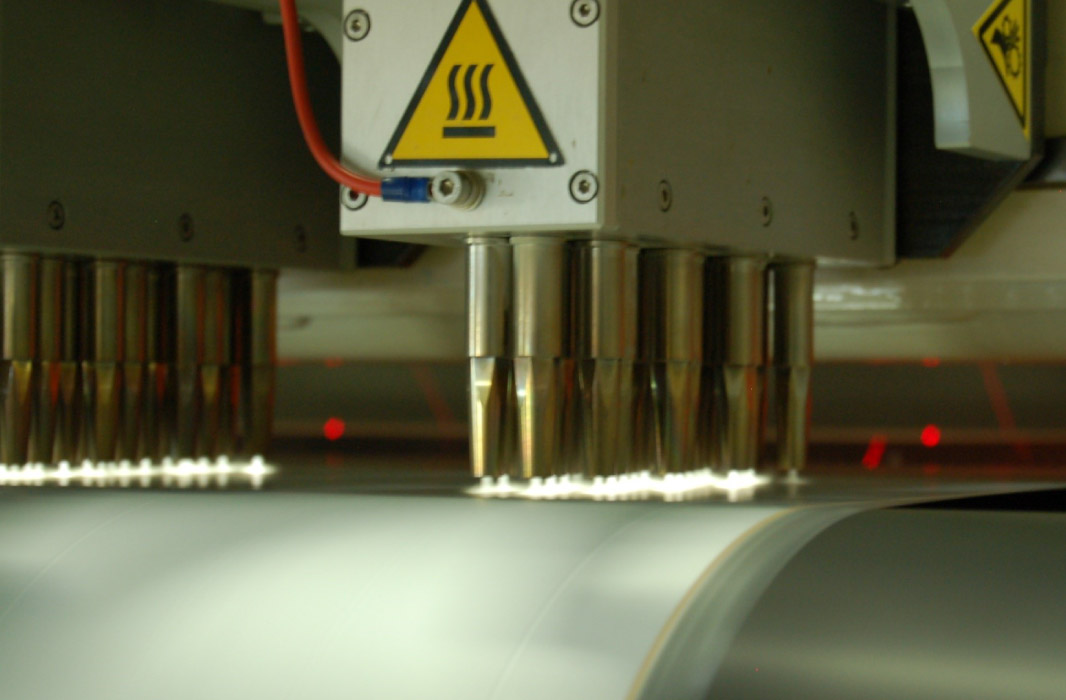

In the dynamic sectors of automotive, aerospace, electrical, medical, household appliances, printing, textile, and packaging, the modification of materials with plasma stands as a crucial preparatory step for further processing. This modification enhances materials for optimal bonding, coating, painting, marking, or printing. The “Zeugma Agile Surface Treatment” (ZAST) platform embodies our commitment to delivering cutting-edge solutions for surface treatment and coating of parts using atmospheric pressure plasma.

Versatile and Sophisticated Solutions

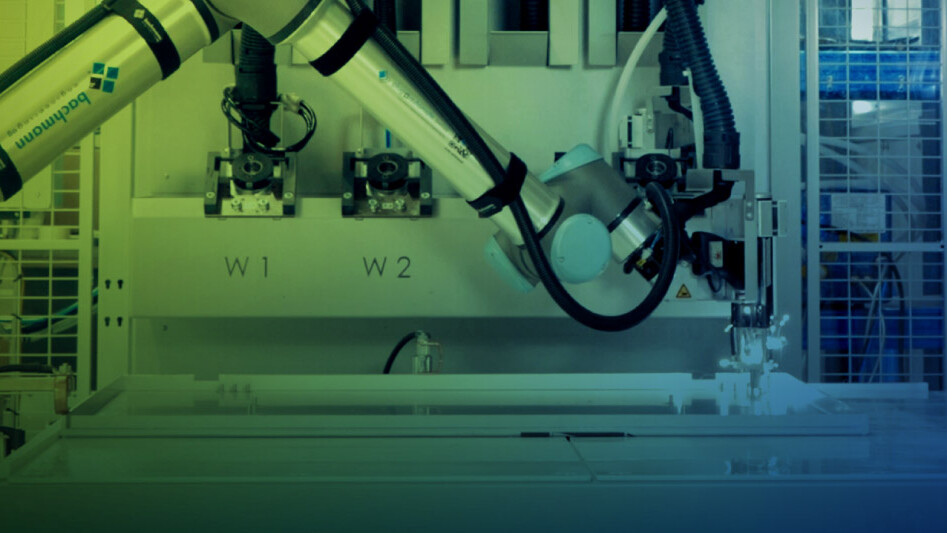

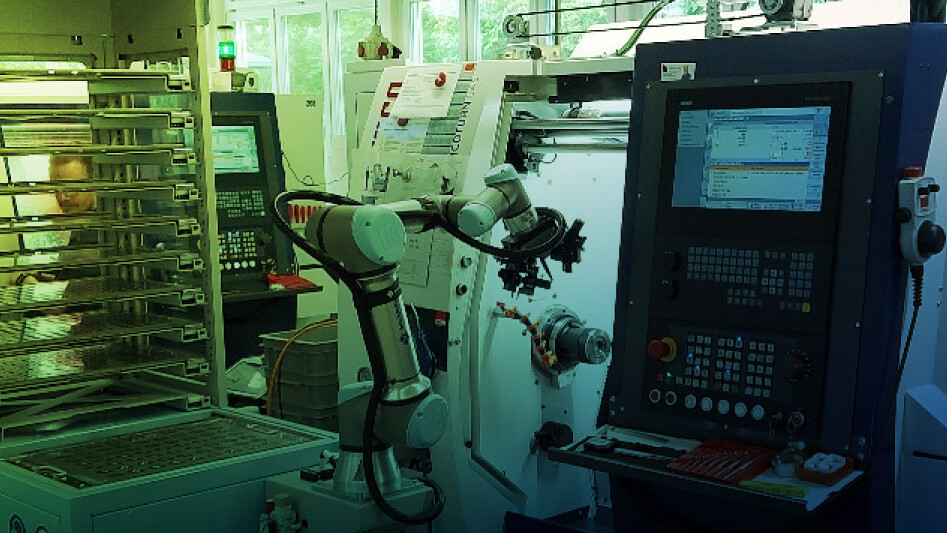

The ZAST platform is engineered to meet diverse industry needs, offering several versions with distinct functionalities, including automatic feeding systems, quality inspection, and marking capabilities. Designed for flexibility, the ZAST product line can serve as either a stand-alone solution or be seamlessly integrated into a full assembly line, evolving to meet any process requirements.

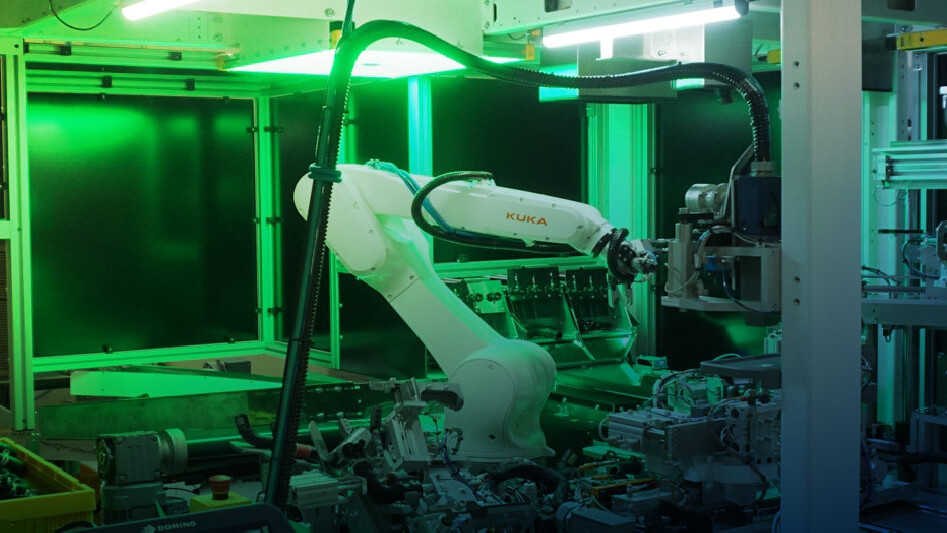

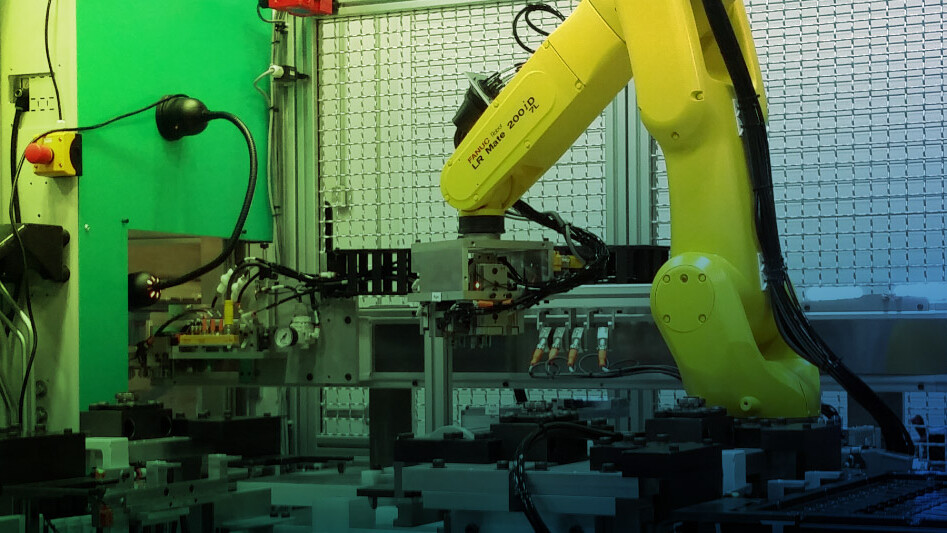

In partnership, IAR Group and Tigres GmbH from Germany bring to the table a comprehensive automated solution for material surface treatment. This collaboration leverages IAR Group’s prowess in industrial automation and Tigres’ expertise in plasma technology to offer global industries automated solutions that not only streamline processes but also mitigate cost pressures and the impact of skilled labor shortages.

Specialized Capabilities

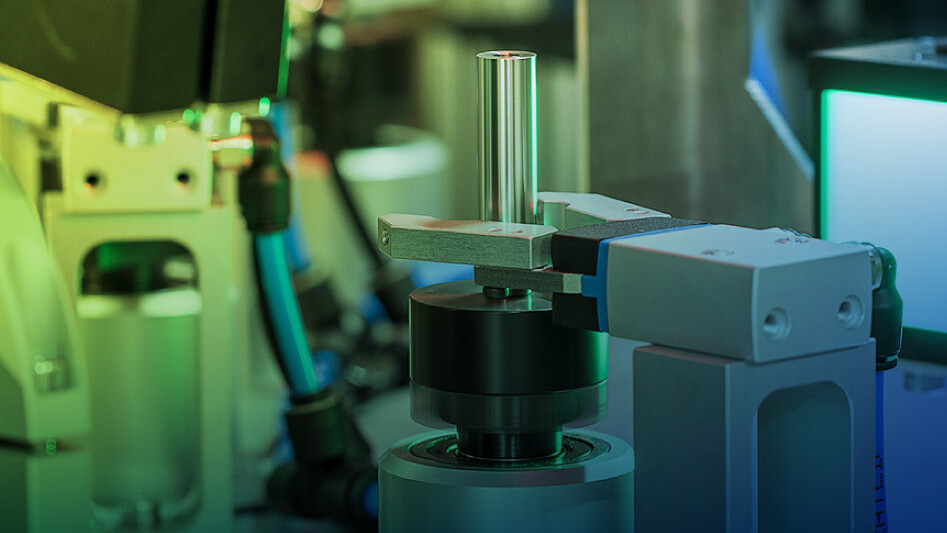

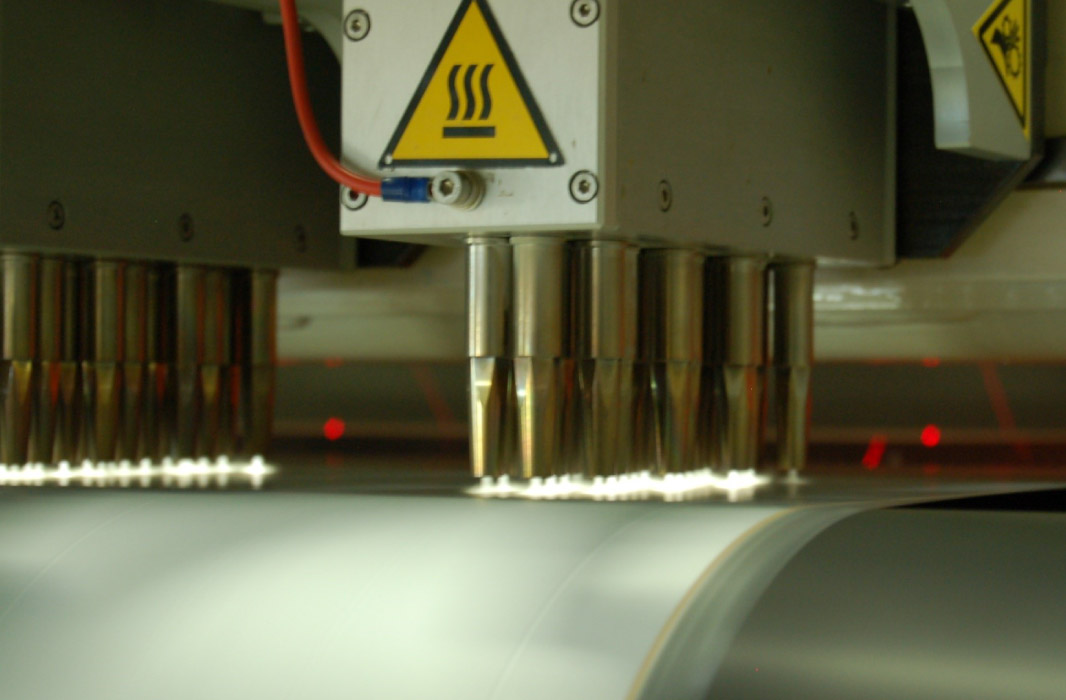

Our domain of expertise covers a broad spectrum, including discrete manufacturing, continuous web surface treatment (Roll-to-Roll), and the treatment of complex shapes utilizing industrial or collaborative robotics. This multidisciplinary approach ensures that materials are prepared with the highest precision and efficiency, ready for subsequent stages of production.

In an era where process optimization and cost reduction are paramount, our automated plasma surface treatment systems offer a strategic advantage, enhancing productivity and quality across a multitude of industries.

Our expertise:

- Precision Surface Modification

- Automated Integration

- Adaptive Treatment Solutions

- Advanced Inspection

- Quality Control

- Robotic Treatment for Complex Geometries

- Roll-to-Roll Processing