solutions

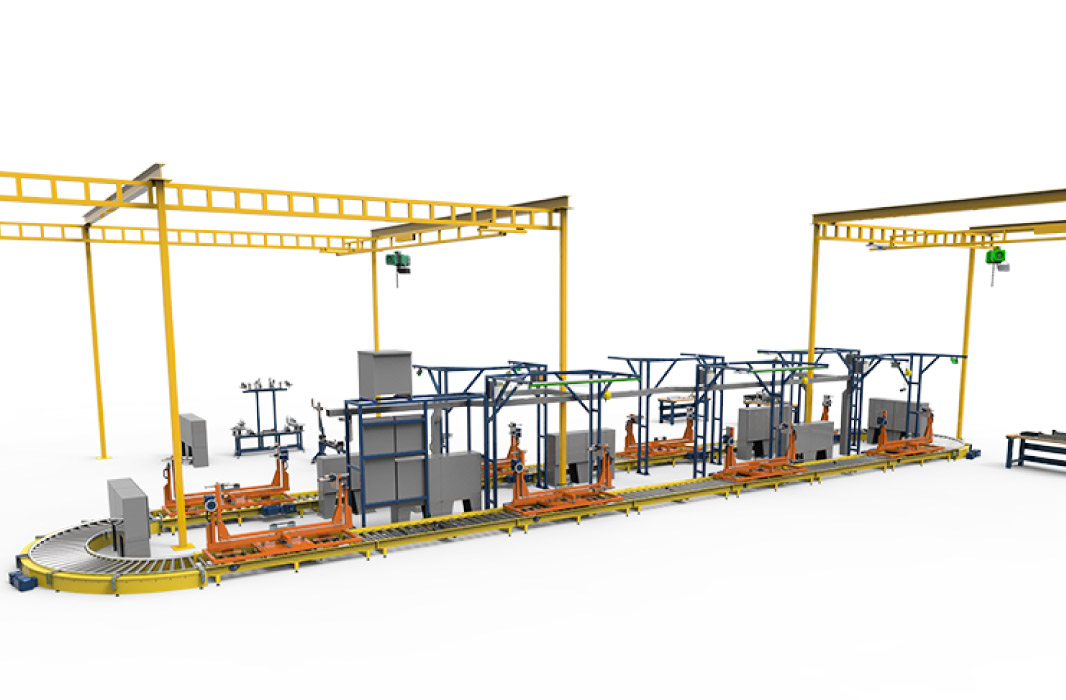

Revolution Pallet System

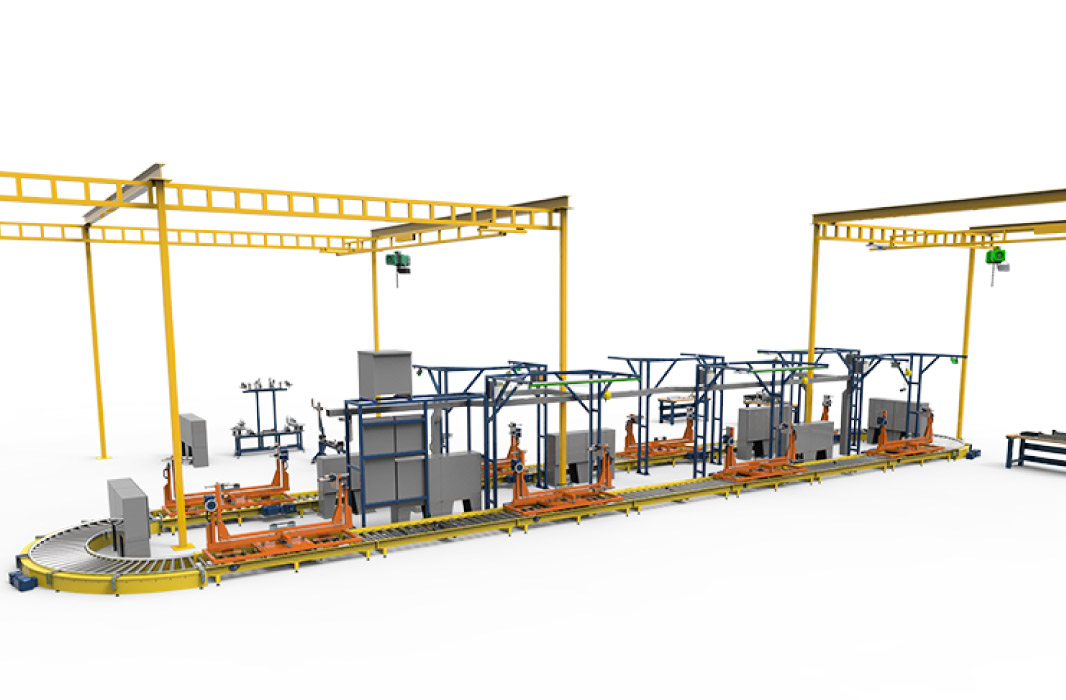

Customizable Pallets for Seamless Product Transportation

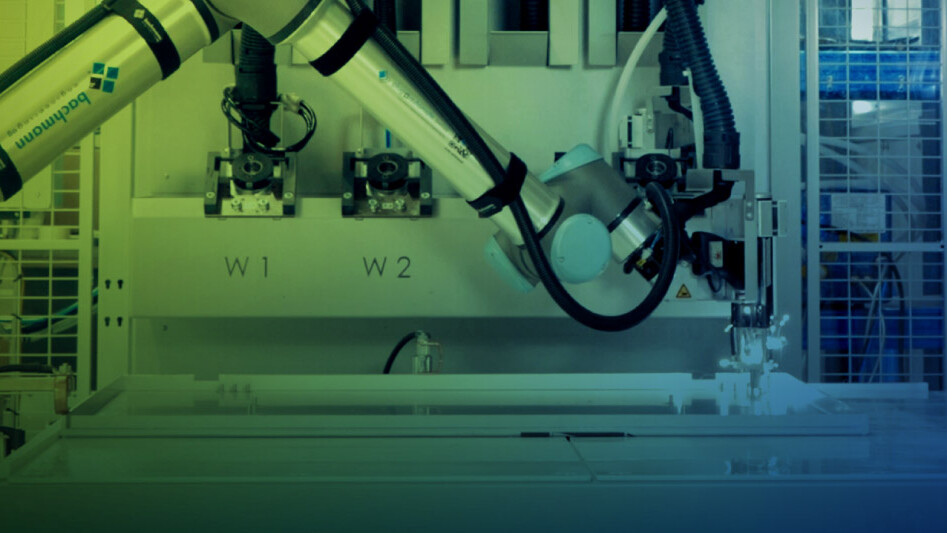

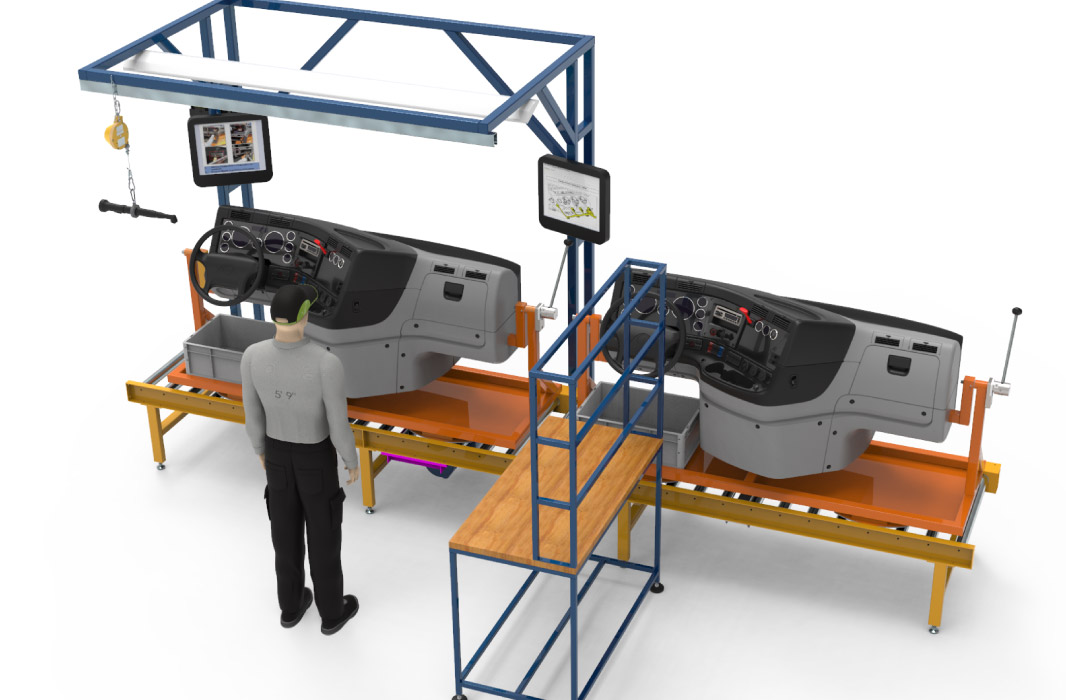

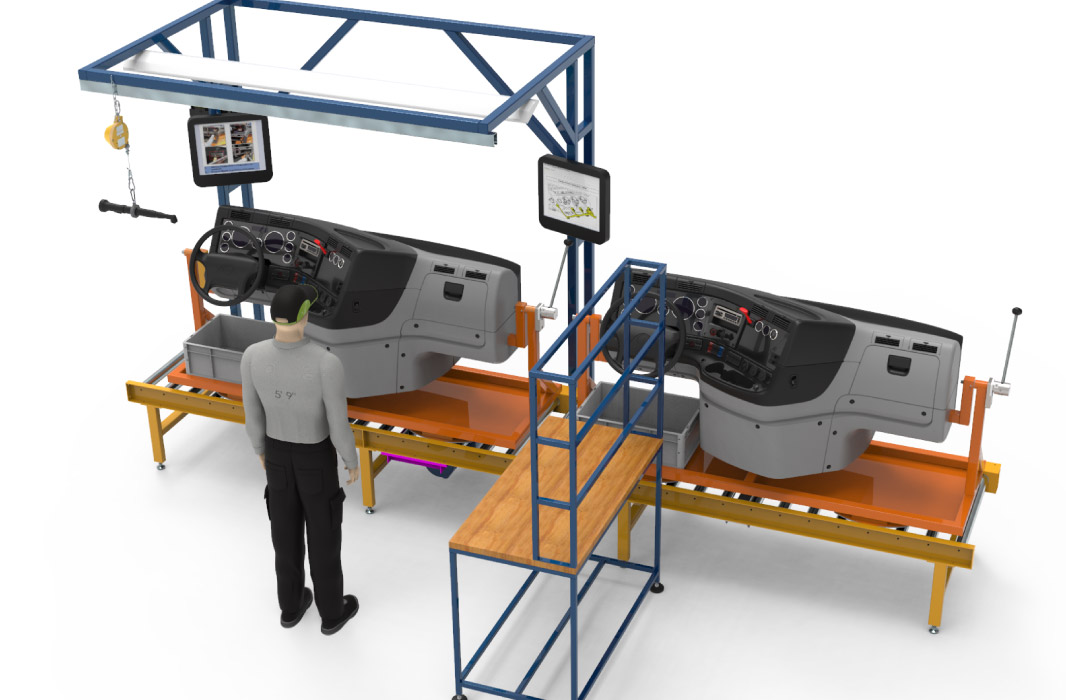

Our unique system features versatile pallets designed to transport products effortlessly between assembly and testing stations. These pallets are adaptable, allowing for the simultaneous production of multiple product models or even bespoke assembly for each station to facilitate a one-piece flow. The design ensures operator access to all sides of the product, thanks to pallets that can rotate in any combination of roll, pitch, and yaw. Safety is paramount; pallets lock securely in position, ensuring parts are perfectly aligned before release. We’ve ingeniously integrated the RFID tag, pallet stop, and anti-tip tooling within the pallet structure to eliminate potential pinch points, enhancing safety further.

Optimized for Efficiency and Safety

The efficiency of our system extends to its ability to accommodate rework and offline tasks. Pallets can be automatically transferred to specialized carts, maintaining part tracking and control while enabling offline work and seamless reintegration into the production line.

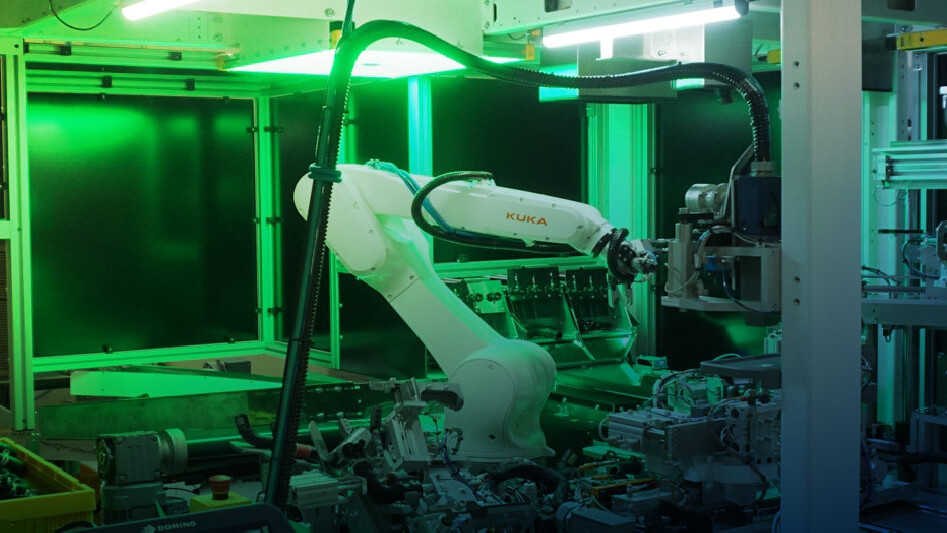

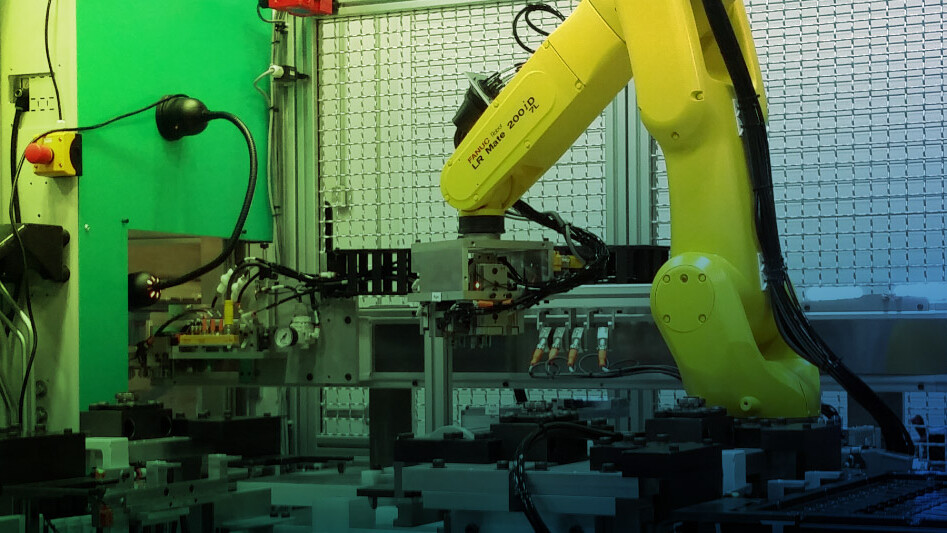

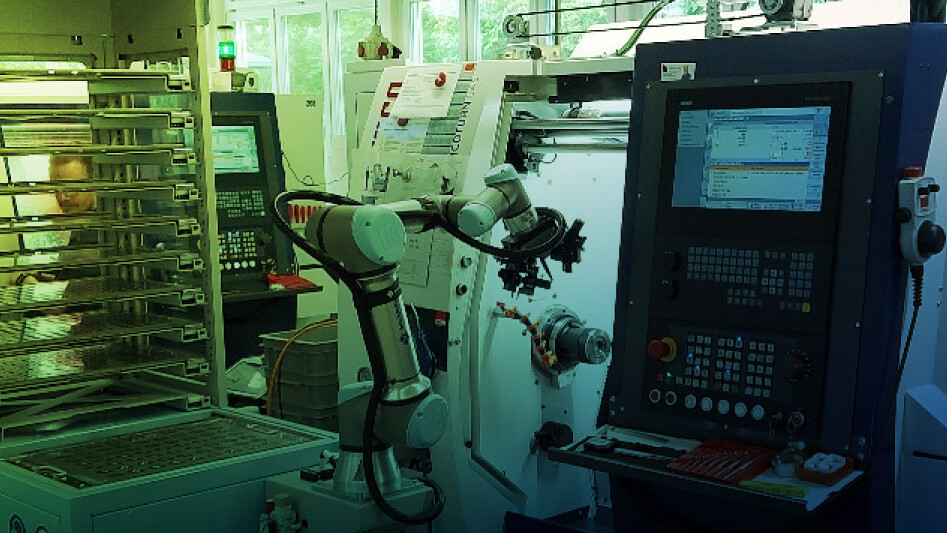

Versatility in Automation

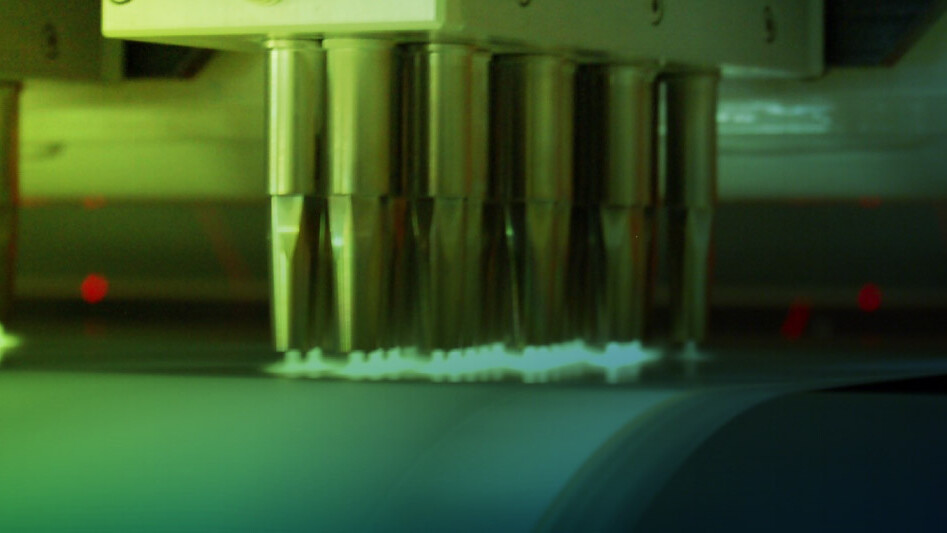

Our system embraces the spectrum of automation, from fully manual to completely automated processes. It incorporates advanced technologies such as pick-to-light systems, actively monitored tool cribs, machine vision, and barcode readers to uphold the highest standards of product quality. At each station, an HMI (Human Machine Interface) or PC provides clear work instructions and immediate feedback to the operator, ensuring precise execution of tasks. The system’s flexibility allows for the configuration of work instructions at a process level, creating custom combinations tailored to each part.

Our expertise:

- Customizable Pallets

- RFID Tagging

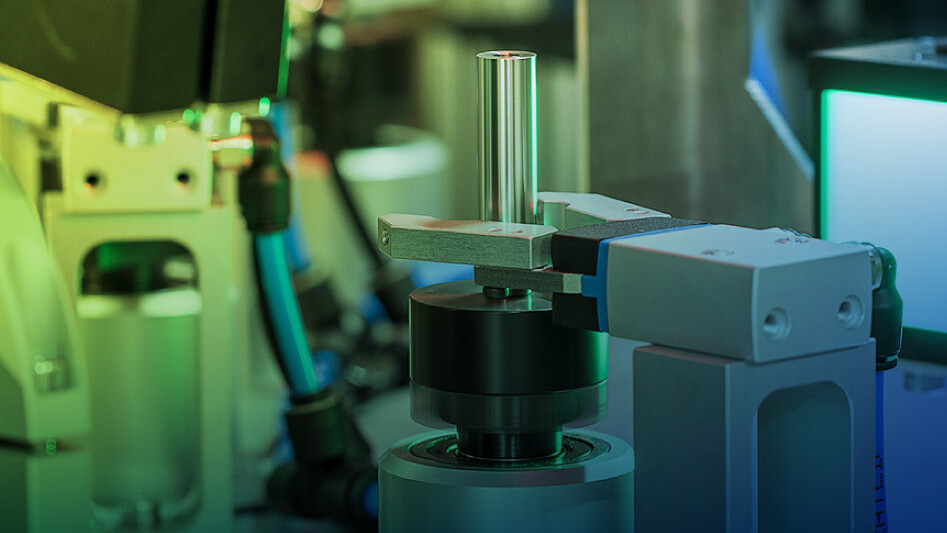

- Machine Vision

- Human-Machine Interfaces (HMI)

- Pick-to-Light Systems

- Automation Spectrum Management